Welcome to the Austin Seven Friends web site and forum

As announced earlier, this forum with it's respective web address will go offline within the next days!

Please follow the link to our new forum

http://www.austinsevenfriends.co.uk/forum

and make sure, you readjust your link button to the new address!

The 1936 'Motor Sport' article on the Twin Cam Austin Seven notes-

"The front axle is tubular and straight, and made in two parts, a joint with an internal roller bearing allowing either of the parts, with its steering pivot, to rotate independently of the other. The suspension is by means of a flat transverse half-elliptic spring carried under the axle tube, and braking and springing torques are resisted by means of radius rods running to the top and bottom of each steering head."

Still not sure how this internal roller bearing is fitted but the flanged joint is apparently involved.

Tony.

The real question is not how it works but what does it actually do?

As far as I can make out, it allows kin pin inclination ( castor ) to be controlled independent of roll, and each side becomes separate from the other. Why would you do this? Well, my guess is in cornering, if you have uncontrolled castor, this can translate into equally uncontrolled camber (think about it, it takes a bit of getting your head around, but I'm right). The result would be increasing positive camber, and therefore increased slip angles just when you'd rather not. This stops that. Quite clever really.

Anyway, Bert Hadley told me it increased cornering speeds by 5mph at Crystal Palace.

The axle needs a slip joint to prevent it acting like a super-stiff anti-roll bar.

Since the radius arms don't meet in the centre of the car (like an A7), without that joint the whole suspension would try to rise and fall as a single unit. In practice, things like radius arms would distort somewhat, not what they're meant to do.

Mercedes-Benz and Auto Union bothe knew that when they built deDion axles on the pre-war GP cars, they have similar arrangements in the de Dion tube to allow relative rotation.

Location: Richmond, Texas

That's where I started, but surely there's easier and cheaper ways of doing that. Which is why I started thinking maybe there's more to it. I could well be reading too much into it I suppose.

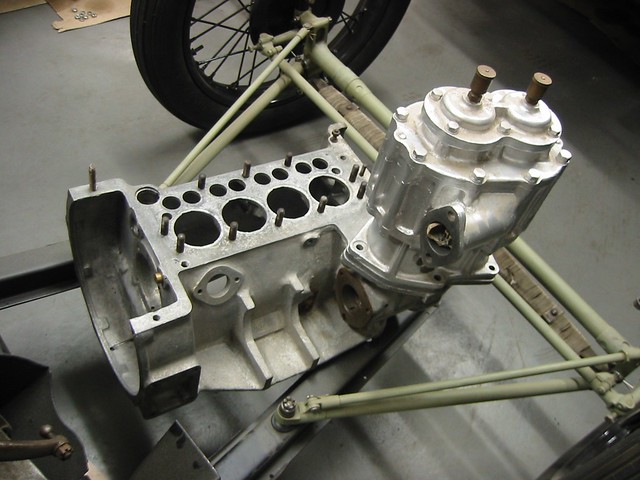

The axle pictured is won I had made.

As I didn't want to pay £1,200 for won for my own single seater. I had a small batch made.

Still got a couple if anyone wants won for £500

Won't be making anymore when theve gone.

Tony.

Location: HUNCOTE on the pig

To overcome the same problem, though at the rear, Saab, VW, and others made axles of split tube that would twist.

I know of no other cheap and easy fix.

Location: Richmond, Texas

Alan, I just caught up with this thread. Do you think that the advantage was gained because it was acting as a very stiff anti roll bar on what I imagine was a very heavy front end? or are you still thinking along the castor/camber lines, or both?

My view is that on a standard Austin chassis the joint would be a waste of time.If anything you want as stiff a front end as you can get.I only encountered understeer on very few occasions and at specific corners. Is understeer a common problem?

Perhaps a stupid question but one that needs asking.

I have seen various tubular axles on Wragg single seaters and other 'twin cam' replicas. These axles have the bolted flange arrangement but are they made to allow the ends to rotate relative to each other? I suspect that some are not, in which case there will be no benefit and a weight penalty over a standard axle beam. Perhaps the main benefit is that they allow a wider front track?

I have seen various tubular axles on Wragg single seaters and other 'twin cam' replicas. These axles have the bolted flange arrangement but are they made to allow the ends to rotate relative to each other? I suspect that some are not, in which case there will be no benefit and a weight penalty over a standard axle beam. Perhaps the main benefit is that they allow a wider front track?

The answer to your first question on rotation is yes. Originally I thought that the purpose was to stop the axle acting as a torsion bar-the radius arms on a TC stops at the chassis rail, and does not pivot centrally as a STD 7 - I imagine that the TC chassis is much stiffer than a STD 7 and that there is a lot more weight on the front from the heavier engine- so that a very stiff anti roll bar would cause understeer. I would have thought that there is not the merest possibility of that happening with a STD floppy chassis. So to answer your second question as to whether some are fixed I too would not be surprised. Your third question as to the benefit of a wider track is also not clear cut as it slows the car down on the faster circuits. I would therefore tend to agree with you that "there will be no benefit and a weight penalty over a stand axle beam". But Alan's input has sown a seed of doubt in my thinking.

Well, firstly, the tubular axle has the spring mounting points well below the beam. This lowers the roll centre. A good thing, probably.

The next bit is a bit complicated for a Saturday evening, so:

It's highly unlikely that they wanted to promote understeer, which is exactly what a straight beam axle mounted like that would have done, so they had the clever idea of a rotating joint in the middle. It begs the question though, why didn't they just lead the radius arms back to the centreline like a standard seven?

I think, and I've no justification because I've no data to back this up, but : when the body rolls, it goes down on one side and up on the other relative to the axle. The radius arms are fixed to the axle so, the castor angles change. The shorter the radius arms, the bigger the castor change. If the castor angle changes, in cornering , you get a camber shift, too, and you can improve cornering by counteracting the drift into positive camber under lateral acceleration. I think this is what they were trying to exploit, but to do it they had to prevent the roll bar effect that they definitely didn't want. Like I say, I don't know, and I could be reading too much into it.

Hi Frank

For a totally rigid front axle and spaced radius rod arrangement not to act as an anti roll bar the short wide chassis between the radius anchor points and rear spring mounts would have to twist to angle of roll of car ; a degree of flexibility unlikely.

Location: Auckland, NZ

Running the radius arms to a central point under the car makes them just about the lowest things on the car and inconvenient to boot.

Location: Richmond, Texas, USA

As an operator of only standard road-going pre 1930 Austin 7s I am not sure I should comment - but it is an interesting discussion on what was one of the fastest of the racing Austins and there are a few things I can't understand -

Alan said

"The real question is not how it works but what does it actually do?

As far as I can make out, it allows kin pin inclination ( castor ) to be controlled independent of roll, and each side becomes separate from the other. Why would you do this? Well, my guess is in cornering, if you have uncontrolled castor, this can translate into equally uncontrolled camber (think about it, it takes a bit of getting your head around, but I'm right). The result would be increasing positive camber, and therefore increased slip angles just when you'd rather not."

In my mind- having the rotationally divided front axle with the two radius arms attached to the sides of the chassis behind the axle, on, say a left hand corner, wouldn't this would cause the king pins to tilt forward on the offside and backward on the near side ?

I can't see how this caster change affects the camber - but if it does then possibly the effect would be different each side ?

Thinking about the many racing specials I have seen with dropped front ends and short radius arms to the side rails - the standard Austin 7 beam front axle would be acting as an anti roll bar - although given the lightness of the beam in torsion possibly not a great problem.

Or is it like the LMB front end- first derided but later used successfully.

Bit early Sunday morning for such taxing thoughts!

Tony.

HI All, One thing to remember cars fitted with this axle will only have a small amount of body roll about 5 to 6 degrees from vertical either way

so the joint takes out any windup in the axel. so caster change would not be great.

Location: Tinopai NZ

My very rough calculation for 6 degrees chassis roll gives around 3 degrees king pin caster tilt with a 24" radius arm - presumably negative and positive- not sure if this is significant in racing calculations.

Tony.

For any curious and grappling with this, the following might assist.

With a vertical kingpin and wheel, the wheel stays vertical as it turns. But not with the kingpin laid back.

A kingpin conventionally tilted backward for normal positive castor causes a wheel turned pidgeon toe style to lean backward toward the car ie adopt a negative camber (at right angles to the turned wheel). The split design increases normal castor on the outside, increasing outside negative camber in the turn. On the inside the turned wheel adopts (desirable) positive camber but as the normal castor is undone, not the amount of change as the outside wheel.

+ and - 2 deg not huge.

I doubt if they thought much about the virtues of negative outside wheel camber in those days as seldom evident in racing photos. Early equal parallel link i.s. certainly stirred interest!

Presumably the splitting reduced the adhesion reducing effect of the antics of one wheel on the other.

Location: Auckland, NZ

Tony, thanks for calculating that, three degrees of castor change is certainly enough to get excited about.

Bob, why do you think suspension design wasn't understood by 1936. I'm sure Murray Jamieson would have known exactly what he was doing.

Gentlemen, I think you're overthinking this.

Without the slip joint, the system cannot accommodate even simple one-wheel bump. Lift one, and the other will rise an equal amount. Roll stiffness is infinite, there is no roll. At least, not until something gives or breaks. Probably the radius arms would twist, I don't see the axle tube twisting.

Location: Richmond, Texas

I struggled for two seasons with a non-rotating tubular front axle and radius arms attached to side of chassis.Despite fiddling I always had severe understeer as Alan can testify.I believe some early Wraggs were built without rotation and suffered similarly.I have fitted a dropped Girling beam with centrally located beefed-up radius arms and the improvement is tremendous.I haven't given up on the tubular job though as it enables the car to be lower to the ground.I just need to get that rare workshop equipment, a round tuit.

Location: The pits,Leicester

Hi Alan

I am not sure if the Brits understood suspension design even in the 1940s. Despite pre war American cars with front anti roll bars, on the Minx and A40 Devon these were fitted on the rear only. Apart from handing aspects, especially unfortunate in the latter case as if on the front would have conserved many roofs.

It is curious that large tyres were not adopted earlier. Possibly the weight, stiffness and drag due the heavy ply construction countered gains.

As mentioned when this topic was previously raised, if had used a light channel for the front axle could have patented the modern torsion beam axle!

Location: Auckland, NZ

did somebody say something?

It is not uncommon for specials over here to be fitted with Big Seven front axles, usually with the radius arms attached to the sides of the chassis al la duck/single seater. My experience of driving any car with this set up is varying degrees of chronic understeer, and increased axle tramp. I have experimented with a Big Seven axle on my own car, bringing the radius arms to the center of the crossmember, my thinking being that wider track and stronger KP's would be desirable. Net result slower lap times, less sharp handling, and axle tramp in really fast corners..... which can be bloody frightening! Needless to say I quickly gave up on that idea, and as mentioned above the weight penalty is not inconsiderable.

Location: Auckland NZ

Alan, as you are our tyre guru ,and I do appreciate your use of "possible" and "possibly" in your replies, can you say whether your instinct tells you that the under steer is caused primarily by the camber change or by the anti roll bar effect of a solid axle, or a 50/50 mix of the two.

For a solid beam axle mounted in this manner, the understeer is almost wholly caused by the very stiff anti roll bar it creates. What I'm hypothesising about is that splitting the axles and allowing rotation gives you the opportunity to take advantage of the castor effect. I think Jamieson would have known that. So, I wonder if the sequence was, he wanted to react the radius arms away from the vehicle centreline because of the camber gain, he realised this would create an antiroll effect he didn't want, so he incorporated the rotating joint.

It is interesting to work out the camber change for say 10 deg turn with say 5 deg normal castor, and with this increased to say 7 deg. Or any other representative figures. If I give my figures they will be wrong as apparently always.

Location: Auckland, NZ

I am sure the main issue is the difficulty of locating a robust radius assembly under a low car.

Location: Auckland, NZ

That is very interesting and explains a lot, thank you.

Whilst on this subject can you explain why so many Austins seem to suffer from understeer? Only a couple of weeks ago Charles Leith mailed me asking for advice, which I really could not give, because of the understeer he had experienced at Curborough having gone to a front mounted track rod and again in this forum many mention it. I ask because I seldom encountered the problem.

Hi Frank,What was Charles Leith reason for moving track rod to the front.

Location: Tinopai NZ

If you move the track rod to the front you can use a straight bar rather than the Austin one which is bent to fit under the chassis. The reason is the Austin bar bends under the cornering forces and doesn't do wonders for toe stiffness.

I've never really had an understeer problem with my Austin, either. Except on the hairpin at Curborough where you have to really nail it coming out to bring the back end round.

However there are those that do. It's often due to too stiff a front end - lots of specials have shortened or spaced radius arms like we've been discussing, even with standard axles. also you need to consider the effect of springs - often the balance is not right front to rear. It's almost impossible to give an answer without seeing the car in question, but what I'd recommend to anyone is ignore the Internet and get a book by Alan Staniforth. He really knew what he was on about and wrote it in a readable manner with a pleasant absence of difficult maths.

I've never really had an understeer problem with my Austin, either. Except on the hairpin at Curborough where you have to really nail it coming out to bring the back end round.

However there are those that do. It's often due to too stiff a front end - lots of specials have shortened or spaced radius arms like we've been discussing, even with standard axles. also you need to consider the effect of springs - often the balance is not right front to rear. It's almost impossible to give an answer without seeing the car in question, but what I'd recommend to anyone is ignore the Internet and get a book by Alan Staniforth. He really knew what he was on about and wrote it in a readable manner with a pleasant absence of difficult maths.

Ah, the hairpin at Curborough, yes. But we only got it on entry for the first two practice runs during which the remains of the tyre softener applied over the winter was scrubbed off. After that everything was fine. Pardon at Prescott was always a bugger because you would sometimes get it there and sometimes not. You often see drivers apparently taking the corner too tightly and loosing grip on the inside, but what has really happened is that the predicted understeer just hasn't occurred.

By the way,we have two cars with short radius arms and one with the std setup which is why I found your reply so interesting and well put.

Depending how done a front track rod will likely change Ackerman, although at racing speeds a reduction would seem likely to reduce understeer. But if too unsuited the forced slip may decrease overall adhesion.

From experience and observation anything which increases instantaneous loads on tyres promotes loss of adhesion and hence if at the front understeer. Dirt track cars reduce s.a settings and fit soft torsion bars when the track is slippery. Some methods of locating the front axle ie locked shackle, short radius metal ended Panhard rod, esp if angled, seem likely to heighten instantaneous lateral loads as car traverses bumps.

Location: Auckland, NZ

I don't think Jamieson was a great chassis-man. Engines, and particularly superchargers, were his forte. Even though Lord Austin had his say-so, no serious road-racing car designer was building a new car with beam front axles by the mid-30s, Bugatti excepted and he had his own ideas.

The joint was first introduced (by Austin) on the Jamieson Sidevalve cars, not the Twin Cam. I suspect the reason is simple. A rigid tubular axle and radius arm assembly doesn't really allow roll at all. So one wheel cannot rise alone, and over the notoriously bumpy tracks of the thirties, particularly Brooklands, they must have been real handsful. Pat Driscall said the car was 15mph faster on Brooklands bankings after the modification.

Location: Richmond,Texas, USA

These pics are of the Duck/Sand racer at John Sutton's about 10 or more years ago and show the later fitted and probably Jamieson designed tubular front axle.

The design is different in detail and may pre-date the Side valve/Twin cam but appears to have a swivel joint on the near side.

The Ducks originally had a forged solid axle and split radius arms.

There is some flexibility in the forged axle but it will behave as an anti roll bar.

Note the damage to the crankcase, probably caused by the chassis twisting in use.

I recently had chance to examine an early model A based dirt track car. The rear axle had radius bars on each side, consisting of a light tubular open triangular frame, apex forward. The front comprised twin light tubular bars, one above the other, presumably only separated so castor could be adjusted. Both arrangements would have offered little twisting resistance. It was not clear if the adjustment threads at the front were locked or free to turn slightly, further reducing resistance.

Location: Auckland, NZ

On second thoughts, with Model A torque tube drive, the rear side mounted radius arms even more compromised than some Seven arrangemnts. But then the cars were not professional designs but amateur copy cat concoctions and only required to run for a few hours. The side sof the triangle section included bends possibly to allow stretch.

Location: Auckland, NZ