Welcome to the Austin Seven Friends web site and forum

As announced earlier, this forum with it's respective web address will go offline within the next days!

Please follow the link to our new forum

http://www.austinsevenfriends.co.uk/forum

and make sure, you readjust your link button to the new address!

A current post which mentioned modern gearbox oil seals reminded me that one topic I have not seen mentioned here is clutch slip. Yet through the decades this had always been a nuisance if not a problem with my car. This despite the relatively enormous diameter of the clutch (many cars with four times the torque had 7 inch clutches). The car was used in a city with very steep streets and often parked and braked heavily (the foot pressure, not the retardation!) down hill, and the gearbox was diligently maintained full. But the mains were never seriously worn, one factor reckoned to promotes slip.

The eventual and complete cure was a modern seal at the front of the gearbox.

I am curious as to others experience. Are most cars now so equipped? Or are gearboxes part filled? Or are steep hills not part of most usage? Or are current linings resistant?

I have old linings, barely worn but slightly oily. I am told a spell in the dishwasher will restore!

Bob Culver

Location: Auckland, NZ

This reminds me of a friend who had his RP engine out quite a few times to cure an oil leak from the clutch housing with no success. I suggested that he changed the gearbox oil to Duckhams which was green, low & behold the oil on his garage floor then changed to green indicating that the leak was from the gearbox & not the engine. Inspection of the gearbox revealed that the input shaft where the rollers run was badly worn and the return oil scroll was unable to work with the increased clearance. A new shaft was sourced and this cured his problem. I noted that he did not suffer from oil on the clutch linings.

I did experience one instance oil on the clutch linings of our 3 speed car many years ago caused by my youthful overfilling of the gearbox. So I concluded (rightly or wrongly) that this was the cause of oil on clutch linings.

Hi

I have had this a couple of times on my Ruby over the years. The first time, I replaced very heavily oil impregnated linings that had the appearance of black glass. The second time, some years later, following advice, I burnt the oil off by slipping the clutch with the car held against a kerb. Since then I have run with a lowered gear box oil level and not had a recurrence.

Regards

Colin

Could I please ask if this is normal practice to keep the gearbox oil below the level of the filler hole? I had a problem with the rear axle oil leaking until Ian Mac suggested I lowered the level, which cured that immediately.

I just wondered if I should do the same to the gearbox to prevent any trouble with oiled linings.

If this is the case, what level is recommended please?

Many thanks

Graham.

Location: Hereford

If it's a three speed box, half a pint is enough. For a 4speed if I had one, I'd use a bit more. Probably two thirds of a pint.

The manuals recommendation is way to much. The only benefit you'll get is the joy of frequently renewing clutch linings.

The gear box oil level is 5/8" below the filler hole. It does not seem to change over time. Whether this is the optimum level I do not know but it seems to work okay for my 1938 gear box.

Colin

Many thanks for you replies.

I think I'll drain and refill with a bit less then.

Thank you

Graham.

Location: Hereford

please be aware, of my gearbox woes on the "4 speed syncro gear box question" thread. I had circa 1/2pt of oil in my 4 speed box and totally B****Red it up. IMHO fit a oil seal to the gearbox input and run the oil level where recommended

Location: Oakley, Hants

With the style of clutch plate fitted to all but the last Sevens, excessive slipping, especially deliberate to burn off oil, seriously heats the uninsulated thin steel disc.

Seems likely the temper temp is exceeded.

Bob Culver

Location: Auckland, NZ

Yes, my clutch is the late type with the linings on the disc.

I wonder how far the level in the box needs to be lowered to stop oil finding its way onto the clutch? It looks like 5/8" is sufficient to make a difference in my gearbox - but I have never measured what volume of oil is still in there. Could be trouble ahead?

Colin

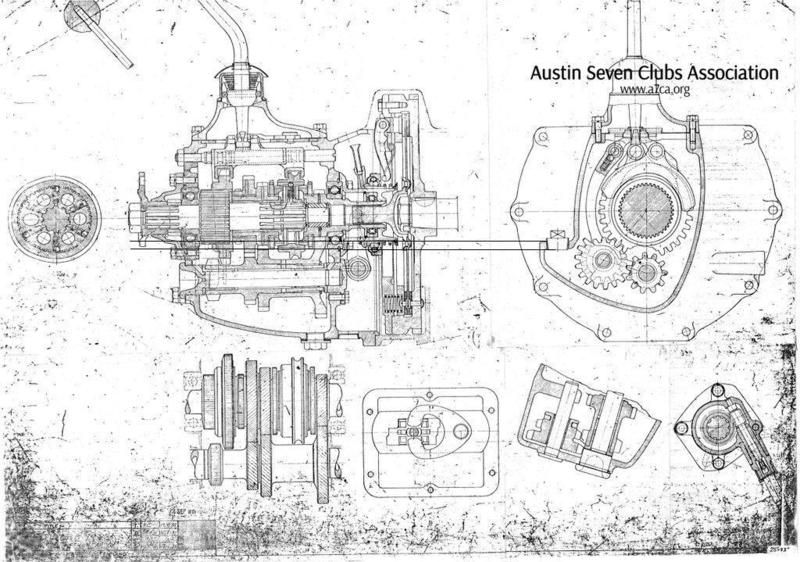

Looking at the drawings of the back axle, I can see how lowering the oil level helps stop contamination of the rear brakes, whilst not harming the axle, given that the crown wheel runs through the oil and must carry it round. But, looking at the gear box drawings, I cannot see how lowering the oil level half an inch or so makes any difference to either the likely leakage or wear of the gear box components?

Colin

The 4 speed box with its plain bearings, often including one after market, and gears turning on the mainshaft is a very different situation cf the 3 speed with all rolling bearings, as Derek has apparently proven, so very reduced quantity seems dangerous.

Capacity is given as 1 1/2pint.

At least one very experienced contributor settles for 1 pint, whatever level that is.

The lower the level the less often the oil sloshes through the front bearing.

Many experienced members must have formed clear views on this over the years

(When being towed long distance it is important that a mainshaft gear touches the oil.)

Years ago my Seven broke its crank 90 miles from home. It expired outside the only house for miles and the owner allowed me to leave the car there. I cobbled together another engine and gearbox and a fortnight later returned with my father and we changed it all over by the roadside. But I had forgotten that the gearbox nose piece screws were only finger tight. It was a long drive home. The “rev counter” kept creeping up to about 8 psi before subsiding back to normal.

Bob Culver

Location: Auckland, NZ

I have always thought that the Ruby gearbox (along with the back axle) was one of the parts of the car least likely to give trouble? If 1 pint out of the recommended 1.5 pints is enough oil to avoid problems, then perhaps running with a reduced level can be used to reduce the occurrence clutch slip even on the late 4 speed boxes?

Colin

Whenever I get a new gearbox of unknown provenance, I take the lid off, drain it and if it looks OK refill it and give it a spin test at 500 RPM on my lathe for about half an hour. I then drain it and examine the drained oil for debris, if there is non and it didn't make an unwanted noises it is put into stock.

I was given a 4 speed 2 syn box this week and remembered this thread and carried out a oil level test:

¼ of a pint - the oil level is barely up to the gear level with only a few drops being thrown up - too low

½ pint - at this level I needed the top on the box to prevent oil being thrown all over my bench.

2/3 pint gives 2” of oil in box measured above the drain plug

3/4 pint gives 21/2” of oil in box measured above the drain plug and 15/8” below the top of the oil filler hole

1 pint gives 3” of oil in box measured above the drain plug and 7/8” below the top of the oil filler hole

11/4 pint gives 31/4”” of oil in box measured above the drain plug and level with the bottom of the oil filler hole.

The measurements were taken with the gearbox top off on the end of the lathe bed, (see photo, the brake drum allows me to put some load on with a piece of 3” x 2”) very difficult in the car.

Then I borrowed my mate's RP saloon handbook 1095A from which I quote on page 15;

Monthly attention

1) examine the oil level in the gearbox which should contain 2/3 of a pint or measure 2” to 2/12” deep.

Then I looked at The Austin Seven Book sixth revised edition by Nicholson page 64, from which I quote:

The gearbox should carry a little over two thirds of a pint which will give a depth of rather more than 2 inches.

On the nearside of the gearbox you will find a plug 2K 8648. When the plug is removed the level of oil in the box can be verified. It should rise to where the base of the plug rests when in position. When refilling the gearbox simply pour in oil until it overflows at the inspection hole.

Finally the Pitman's book of the Austin Seven And Eight third edition reprinted 1951 page 16 from which I quote:

Remove the combined level & filler plug, if this has not already been done and fill up with a pint and a half of new oil which is in readiness. This should give an oil level up to the bottom of the thread in the plug hole.

If you follow Nicholson's advice , until it overflows the inspection hole the first & third motion shaft bearings will be flooded (see drawing) and I wouldn't be surprised if return scroll is overwhelmed and oil found it's way into the clutch. I like Nicholson's 'a little over two thirds of a pint' (how little?) and Pitman has found that the Austin recommended oil quantity of 2/3 of a pint needed to be increased to 11/2 pints for some reason that is lost in the mists of time.

I leave it up to you to decide how little over two thirds of a pint you put in your gearbox.

I seldom enter into the forum discussions as it often attracts responses which include endless twodle from those who should know better. However Dave Mans entry regarding a 4 speed box is very interesting. I have just carried out a similar exercise with much the same results.The conclusion was that The minimum quantity is 1/2pt. This ensures all lay gears are sitting in oil. (this is the level I use when racing and never had a gearbox failure) The ideal level seems to be between 3/4 and 1pt. (.5 ltr) The Austin Ruby Hand book and the Castrol chart says 1.5Pt but this level seems too high and I would not be surprised if leakage occurred.

I don't trust the Castrol chart as it also tells you to fill the rear axle to the level of the filler plug which on later cars is almost at the top of the axle case! I find about 1/2pt (300ml) is adequate for all rear axles.

Vince

Location: Moonraker country

Thanks Dave and Vince. The sort of authoritative response which I seek but do not always elicit!

For decades the only info for my car was the Pitmans book. Outside UK Club circles, little else was available.

I have regularly commented on the need for some universal guide. Practical oil levels are the sort of info which needs to be detailed. What does the PWA7C pamphlet suggest?

For other cars without a dipstick the usual convention is to fill to at least bottom of the filler hole.

Nicholson somewhat mixes early and later models.

For cars which leak oil a margin for long periods without checking had to be allowed.

Sevens do strange things and the possibility of a protracted 1 in 7 climb in 2nd has to be allowed for. Perhaps Derek explored this.

In makes with all rolling bearings, suffices if a revolving gear dips. But with plain bearings nice to have the layshaft covered, whatever quantity that involves.. The 2nd running on 3rd is a bit unusual and experience may have prompted a revised level recommendation.

But if running a low level caution is necessary towing as the layshaft does not rotate, unless the clutch is depressed occasionally, or wedged down (which, with no pilot bearing, is realistic)

My car was stored for decades and the felts shrunk. When the diff was refilled to the hole, oil dripped out the loosened hubs!

Bob Culver

Location: Auckland, NZ

Hi Dave, in the main

Like much else on the Forum this doubtless qualifies as twaddle, but, true to form, Nicholson advises “to catch the outflow, use any old vessel that will take, say, one pint.”

Those who followed his advice to fill to the brim would be in for another surprise.

Bob Culver

Location: Auckland, NZ

I'm reading LTC Rolt's second part of his autobiography Landscape with Canals, in which he refers to his wartime mode of transport a 1938 Austin Big Seven saloon. He describes it as a terrible little car in every way, he was used to his father's Alvis. I quote :"It used to suffer from bouts of clutch slip due to oil that found it's way from the back main bearing" Now I don't understand how oil from the rear main bearing can get into the clutch, it will be thrown off the flywheel to drip from the bell housing drain. More likely the gearbox had been overfilled.

Hi Dave

I wonder what LTCR would have made of the typical well used small Seven of the time, devoid of brakes, and with harsh rumbling mains, a top speed of 45 or less due carbon, burned valves, and retarded spark. To the common folk a Big Seven was considered very refined! (almost as good as a Morris 8!)

For anyone interested in the development of machines and processes LTCR’s book Tools For The Job is a good read. It all seems so obvious with hindsight. For the first steam engines there were no facilities to bore so were cast in brass and file finished!

Bob Culver

Location: Auckland, NZ

Thanks everyone - now I understand how a lower oil level can work.

Regards

Colin

(The letter code read 'mUppET')

I seem to recall in LTCR's third part of his autobiography he makes some non so nice comments about driving a chummy Bob. Yes Tools For The Job is an interesting book

Here you are Reckless

Incredibly the 1957 Austin Motor Co book Austin Cars 1936-39 publication 843/C lists 1 1/2 pints. By that time would expect them to have got things sorted... but then they never got front axle ends and kingpins sorted. The Co seemed a bit careless about publications throughout. The pinion shaft in the parts book is especially odd.

My guess is that any weakness would be the 2nd gear on 3rd and that on the mainshft when grinding up endles hills in 2nd. Most other cars the gears are stationary relative to the mainshft when under load; some dispense with bushes.

Is excessive wear sometimes found in these places?

Location: Auckland, NZ

Just to Throw a Little more Oil on the Linings.

I had reason to remove my Type 65 engine not long after a clutch reline and I found something you might find of interest.

On the flywheel clutch linings oil thrown out of the rear main had gone onto the clutch lining through the rivet holes,

I had just taken the engine out at the right time to see this as each rivet had a circle of oil around it on the lining.

I took the linings off and re riveted them using gasket goo to seal the rivet shanks.

They lasted till they went down to the rivets afterwards.

I have always used gasket goo on the rivets since then.

I have never had a problem with oil coming out of the gearbox nose ( Yet )

I have only been ab-using the car for 25 years

Thanks Richard - good tip.

Nick Turley

Location: The Centre of the Universe