Welcome to the Austin Seven Friends web site and forum

As announced earlier, this forum with it's respective web address will go offline within the next days!

Please follow the link to our new forum

http://www.austinsevenfriends.co.uk/forum

and make sure, you readjust your link button to the new address!

Hedd,

Quote

"If al else fails, cut out the little mounts with an angle grinder and dress the inside of the water space with a dremel (boring job) and then make a little T shaped insert in steel. Fixed forever then!."

Can you elaborate on this please, particularly the T pieces. I have a really good standard bore block where the bolt holes are much enlarged and the area round them well corroded.

Maybe a drawing?

Location: Bonnie Galloway

Dave, simply cut out the existing mountings for the side water manifold, this can be accomplished in situ with an angle grinder.

Dress the inside face of the block casiting (the outer to the water jacket) using a dremel or similar (or a file bent to 90 degrees) so that the surfaces are flat.

Then make two of these in steel, if the inside faces of the block are not flat, you make the T piece to suit. You dont need a milling machine to make them, though it does help. You can do it with a saw and a file.

They are a bit fiddly to get in, but I superglue them in while putting the gasket and water manifold on.

I've just had some castings made to secure the side branch with 4 3/16,2BA or 5mm screws for damaged blocks as another option.

Thanks Hedd, Ruairidh and Austin ITS.

A few options there.

Location: Bonnie Galloway

The auzzies also make a bespoke casting for the water branch. Its mounted by 4no 1/4 bolts/studs that you drill and tap into the block flange a bit like Terry's plate.

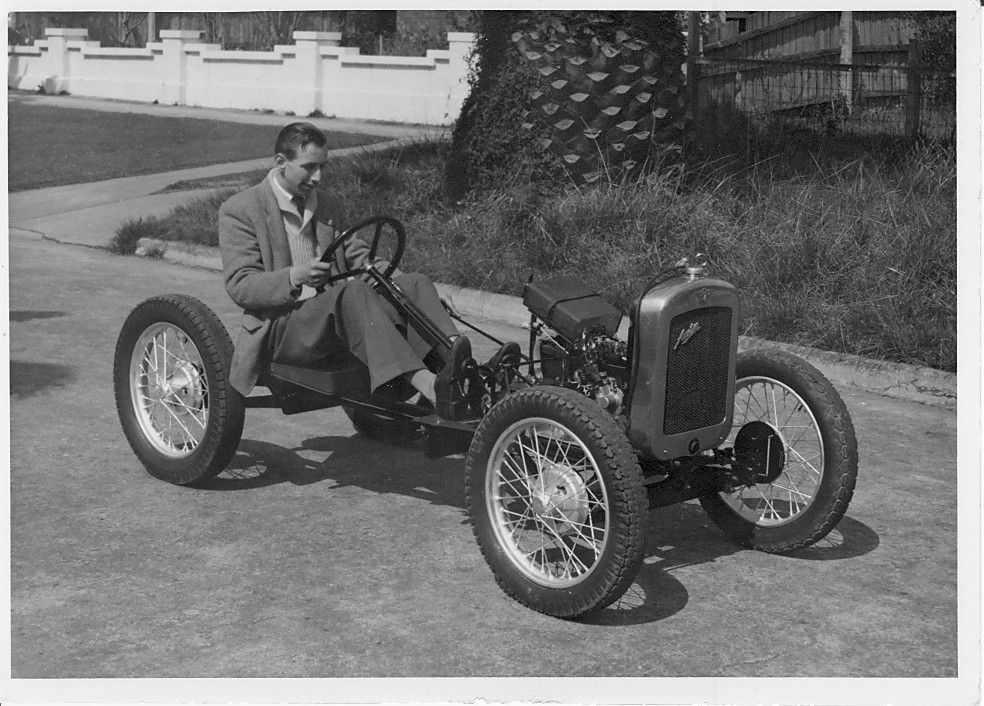

Bill was kind enough to procure me one and sent it over a while back. you should be able to make it out in this picture.

this may well be the same idea as Austin in the Sheds suggestion?.

However you do a repair or whatever method of fastenings you use, make sure that they is a clearance between the end of the studs/bolts/set screws/machine screws and the outer surface of the bores within the block when the water branch is tightened down. Very easy to distort the bore if you don't. Not something I've ever done but I have seen a block with a raised 'dimple' to the middle of one of the bores where clearance wasn't allowed for

Steve

Location: North Yorkshire

Malcolm will tell you a story about 'someone' who did the same to a petrol tank (full) when fitting a bracket for a coil

One of those things I'll, probably, never live down!!

Steve

Location: North Yorkshire

The Australian 4 stud water manifold has the advantage of removing the studs from inside the water jacket thus eliminating electrolytic corrosion, (that is provided you seal the threads properly.) Although not original in appearance they are a good solution and I am surprised that they have not become available on the UK market.

Location: Auckland NZ

Bill was kind enough to procure me one and sent it over a while back. you should be able to make it out in this picture.

this may well be the same idea as Austin in the Sheds suggestion?.

Castings are done but I haven't got them back yet.

Do I see some 'Ignition lever on steering box', part number BM 143 in the bottom right corner ?

This should help Stephen Bryant.

Tony.

Location: Melbourne, Australia

Yes they are Tony,which is for mag and which for coil ign?

I've only had a few cast as I have 2 cars with them missing but there are some spare ones.

Magneto BM 57, Coil BM 143 but looking at them on Magneto and Coil 7's they look similar in length and difficult to measure accurately in place.

Tony.

Location: Melbourne, Australia

I don't know either,I'd hoped someone else would answer it.

I think the short one is mag,will look at my coil engine cars tomorrow.

I hate to think of you tossing and turning Ruairidh- in the other discussion on control levers the length has been quoted as 1" and 3/4".

I have just looked at them on the cars, but a 1/4" difference is hard to see in the grime.

Given the magneto control movement looks longer than the distributor control movement (and has a secondary lever in the system) then the magneto lever is possibly the longer of the two?

Tony

Location: Melbourne, Australia

So,

Jumping back to the original quandry.... I've ordered some BSF taps & dies to help me clean the threads in the block...

(I also thought I might _very carefully_ drill the hole through and cut a little more thread on it - it doesn't seem to go all the way at the moment)

The taps & dies have arrived - I've not used taps & dies since college (though I can remember about winding in backing them out etc) before going anywhere near the engine, I thought I'd try them on a nice clean 5/16 stud & nut - they bind after one turn - looking closely, it would seem that whilst the TPI on them is right, the tap is a good bit fatter than the nut, and the die is a good bit smaller than the stud.

Is this deliberate, maybe to allow for the metal they remove somehow? As I wasn't going to be using these much, I have bought cheapo ones, which I accept won't last. Is it possible they're totally wrong?

Phrasing this a different way (and being very aware I'm probably missing something fundamental) if I take a tap & die of the same size, should it be possible or at least nearly possible to thread the die over the tap?

Confused as ever!

Cheers,

James

Location: hove

A quick postscript to the previous post.

I decided I was being a bit of a wus (spelling?) not at least tentatively trying the tap on the holes in the blcok, so I did - it worked beautiffuly to clean out the threads without cutting any new metal.

And I now realise that they are drilled & tapped right the way through - it's just that the last 2 or 3mm was full of disgusting crud. It isn't now, and my lovely new stainless studs fit nicely, and even feel fairly secure!

I'm still intrigued as to why the taps bind on a nut that fits the self same threading though.....

Cheers,

James

Location: hove

Yes R you are correct,Longer one for mag.

Sorry to be so late adding my two pennyworth; I don't look on the Forum very often. I always use fibre washers and dome nuts on the studs (which must be the right length, shortened if necessary). This avoids the need for countersinking, O rings etc. A bit of jointing paste on the washers makes sure it is 100% watertight. I do prefer to use stainless studs and brass or stainless dome nuts. Earlier comments about repairing block bridges are still valid.

Location: Near Cambridge

I use stainless steel studs and brass or stainless dome nuts with fibre washers. The studs must be the right length to allow the nuts to tighten on the washers properly. Use a bit of pipe jointing on the washers if you want; fibre washers are not what they used to be, not much 'squash' in them these days!

Location: Near Cambridge