Welcome to the Austin Seven Friends web site and forum

As announced earlier, this forum with it's respective web address will go offline within the next days!

Please follow the link to our new forum

http://www.austinsevenfriends.co.uk/forum

and make sure, you readjust your link button to the new address!

Hi all,

I have owned a '36 Ruby for nearly 4 years now and keeping an eye on this forum ever since buying it. About 2 years ago, the three bearing engine lost oil feed to the centre bearing and made quite a mess (and a real good clattering noise till then) necessitating engine out and discovery of all the common issues that have been described on A7 Friends in great detail many times over - broken oil feed, loose cylinder block studs, less than ideal centre bearing setup, oil leaks for Africa, broken bearing lip, split front pulley, and so on.

I took a hiatus from it for a while and thought long and hard about what I wanted to achieve with this car. I love it's looks, all of it's many interesting design features. They really are a lovely little car for a whole bunch of reasons, but mechanically, being the heaviest A7, even with 17hp, it really struggles to hold pace up any sort of gradient and can be hampered by wind direction even, and with my wife and 5 year old daughter aboard with various bits and pieces, even a short trip with a few hills in the mix can be noisy, smokey and terrifically slow. Generally it is in okay shape, but pretty tired and not as wonderful as many I see here.

Anyway, after careful consideration, I decided that an engine swap would potentially be a good option for this car, spurred along by three pictures I found of a blue Opal in the UK that has an A35 engine in it (supposedly). I had also read Bill Williams' A7 Specials book, looked at the forum and at what my options were with the original engine - Phoenix crank, 2 bearing conversion, 12v, high compression, potentially supercharger and the not insignificant costs of doing so and still not bulletproof by any means and decided this was not an option for me personally either. Reliant engines do not really exist down here in the Antipodes, so that was out too. I did not want to make it faster in terms of top end (let's face it, anywhere close to 50mph is pretty exciting in full bodied Ruby), but to allow it to maintain it's speed through a sensible upgrade, a more even spread of gears, 12 volt electrics, but still have the 'feel' and characteristics of an 80 year old car - even if many would say that it was not possible when changing the engine.

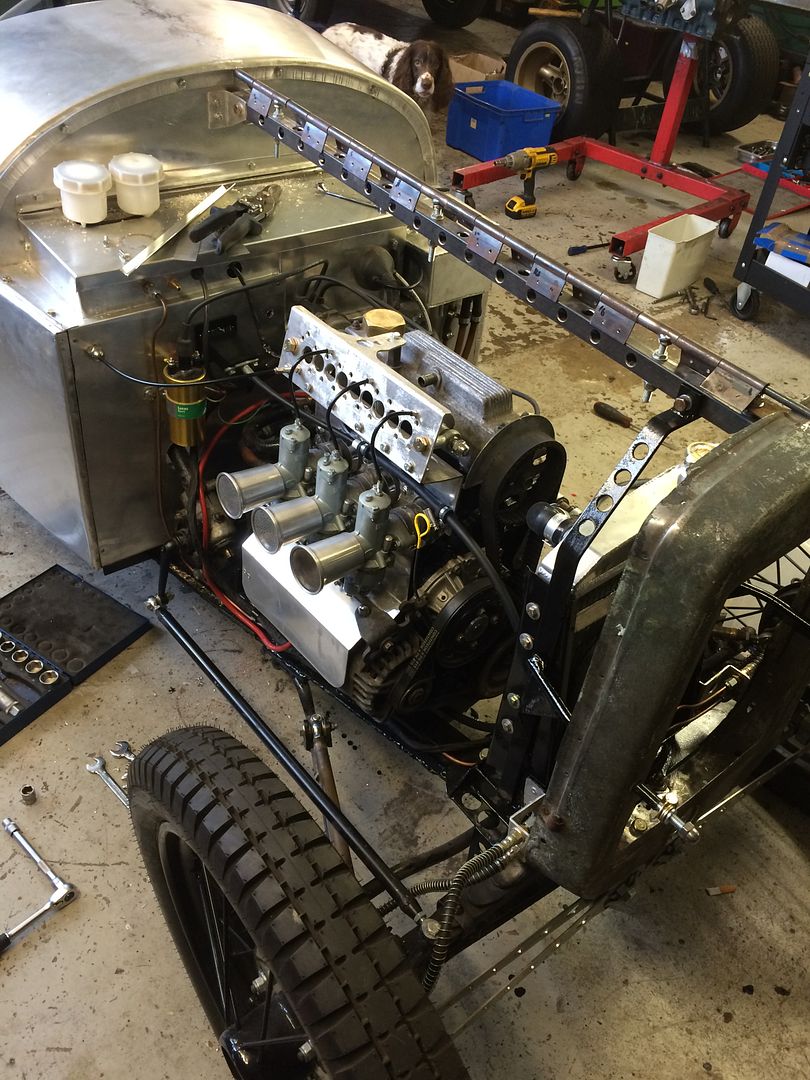

What I have come up with is the fitment of a 1000cc 4 cylinder Suzuki F10A and 4-speed from a 1982 Suzuki SJ410 (Samurai) that I picked up complete for $200 NZD (about 110 GBP) with all the stuff I needed to make it run. It was picked for it's compact size (sump fits between the chassis rails right to the front), non-hydraulic clutch, gear ratios very similar to sports ratios (very close to speedex ratios) and because being Suzuki, it is a well engineered little motor that loves revs and is strong. It is single overhead cam and made 43hp stock off the assembly line, but admittedly a bit less now after 35 years of service.

I have mounted the motor and box solidly to the chassis in similar form to the original A7 design and apart from four new holes in the rails, there is no chassis modification. I retained the pull control for starting, original gearknob, made a new gearbox cover to suit and sit close to the gearbox (which intrudes less into the cabin the the A7 one), modeled the clutch pedal operation to be like the A7 originally (directly on the bell housing, about 1.5 inches of travel and reasonably heavy too, using the same pedal so looks original), also retained the A7 radiator with an electric fan and thermostat. Unfortunately I did end up having to cut the firewall more than I had hoped - final engine positioning got tricky and the distributor was further back than I had wanted, but out came the battery / tool boxes and in went a couple of new removeable sections to close the firewall in around the back of the engine, and pretty unoffensive to the untrained eye. I intentionally cleaned, but did not paint anything, and avoided anything too shiny and new. it looks like it has been in there for years, and is in keeping with the rest of the car.

Anyway, it is still not completely finished, small jobs still to do, and brakes need overhauling to get them as good as I can, and then off for certification.

Now it is substantially completed, what do I think of it you may ask? It is fantastic. It is quiet(er), lovely choice of gears, accelerates similar to a Mini, and can hold reasonable speed - a hill on my way home from town where 12mph with a spirited run up was typical, is now possible at 25mph in third, running rough with a partially blocked carburetor (tank has since been cleaned). Very bright lights, good charging system, and overall very driveable. I do wonder how the rear axle will hold up in the longer term as it is now the weakest link, but they seem to survive okay in specials with similar power and subjected to a fair amount of abuse...?

Some would shoot me, others may salute me, but I think it is great when a car goes better at 80 years old than brand new. :)

Here is the proof of my work / stupidity:

Location: Whangarei, New Zealand

Nice work.

I've used a Suzuki G10A 3 cylinder in my special. Goes like stink !

Did you use the injection and ecu ? Biggest problem to work out on mine was the ignition advance with out using the ecu as I've got mine on amal carbs.

How did you do the speedo drive ?

HI Alex.

that is a very neat installation and like you said in keeping with the rest of the car, there will be no problems going Both ways over the Brynderwyns now.

do you have a photo of the inside.

Cheers Colin

Location: TINOPAI NZ

I've used a Suzuki G10A 3 cylinder in my special. Goes like stink !

Did you use the injection and ecu ? Biggest problem to work out on mine was the ignition advance with out using the ecu as I've got mine on amal carbs.

How did you do the speedo drive ?

Thanks John, I have poured over your Photobucket page a number of times in close detail and with great interest - I love what you have done an can't wait to see it finished as it is a very pleasing design aesthetically and functionally. I love seeing something a bit different but still true to the original idea. The G10A is quite a potent motor for the weight and size of your special - 55hp or so depending on which variant you have - I'd be a bit weary of driving it hard personally, but it must be sensational. :)

The F10A being a much older engine than your G10a has a distributor and is carbied, and has a sidedraft design single choke factory carb which can be swapped directly out for a 1.5 inch S.U. apparently...?

Good question as I see you have the same issue. The speedo drive is one of the failings of this project. In the early stages, I thought 'no worries, I'll adapt the Austin cable to the Suzuki gearbox and it'll be fine'. What I realised once the engine was sitting in there (even though in reflection it was really obvious) is that there isn't a speedo output on the gearbox. Coming from a four wheel drive vehicle, the speedo output comes off the transfer case, which is a divorced / separated unit in the SJ410. There isn't a RWD gearbox to suit this motor apart from that in a Supercarry van, which is cable shift and mounted at a funny angle as the engine is nearly horizontal, so comes with even more issues to solve to use it. So, I'm in a similar camp to you John - Hall effect sensor/gauge, bicycle speedo, or a GPS guage, none of these are options I had hoped for at the start, but can't win on all fronts I guess, and it is one of the last small things left to sort. I've been putting it off in hope of finding a better answer!

Alex.

Location: Whangarei, New Zealand

Good question as I see you have the same issue. The speedo drive is one of the failings of this project. In the early stages, I thought 'no worries, I'll adapt the Austin cable to the Suzuki gearbox and it'll be fine'. What I realised once the engine was sitting in there (even though in reflection it was really obvious) is that there isn't a speedo output on the gearbox. Coming from a four wheel drive vehicle, the speedo output comes off the transfer case, which is a divorced / separated unit in the SJ410. There isn't a RWD gearbox to suit this motor apart from that in a Supercarry van, which is cable shift and mounted at a funny angle as the engine is nearly horizontal, so comes with even more issues to solve to use it. So, I'm in a similar camp to you John - Hall effect sensor/gauge, bicycle speedo, or a GPS guage, none of these are options I had hoped for at the start, but can't win on all fronts I guess, and it is one of the last small things left to sort. I've been putting it off in hope of finding a better answer!

Alex.

Is there room to install a belt drive for the speedo cable? The Suzuki boxes I've seen have drive flange propshaft output. If it does have such and there's room to machine a groove in it, you could use a small round section belt as it isn't delivering any significant power.

IIRC the speedo drive on the Seven gearbox gives 4:1 reduction, so should be just about do-able with two pulleys without the speedo cable pulley being too large. Also if you can make this work, you'd be harking back to the earliest Seven models, where the speedo was belt driven