Welcome to the Austin Seven Friends web site and forum

As announced earlier, this forum with it's respective web address will go offline within the next days!

Please follow the link to our new forum

http://www.austinsevenfriends.co.uk/forum

and make sure, you readjust your link button to the new address!

Hi Bob.

Many thanks for the very helpful advice. with yours and everyone else's input, this should end up as a pretty bomb-proof engine!

M.

Location: Herefordshire, with an "E" not a "T".

OK. Feeling quite smug at the moment.

As suggested, I had the cylinder bores measured and was rather pleased with myself to be told that all of my primitive measurements were spot-on - well, within 3/10 of a thou, anyway.

I then got to work with the honing tool/deglazing bar (?) - cautiously, fortunately. It opened up the bores at about 1 thou every 30 seconds and the previously undersize bores are all now +.060" and appear to be within tolerances of +.0005", -0.

However, pride come before a fall and my sharp-eyed son brought me down to earth by pointing out a crack in one of the mounting lugs on the crankcase. It looks weldable, I've just got to find someone who'll do it.

Location: Herefordshire, with an "E" not a "T".

Hello Martin, when you find a welder could you let me know as my 1928 early coil crankcase is also cracked.

Regards

Stuart

Location: Staffordshire, the creative county.

Regards

Stuart

Yes, certainly, Stuart.

Location: Herefordshire, with an "E" not a "T".

I seem to remember from years ago people recommending only using 3 mounting bolts so the crankcase didn't attempt the impossible stopping the chassis flexing. There's your money saving alternative, don't use that mounting lug!

Location: Isle of Wight

Martin,

Well done with the dimensions and bore honing; one up for impecunisity. On that theme, if the crack isn't through to the oily side I wouldn't think about welding. Bolting all four up hard may have contributed to the crack. Just bolt the other three up with a spacer washer to lift the cracked foot away from the chassis?

Dave

Hi Martin

I am just going through the same process as you except being an Austin 7 virgin, I completely assembled the engine and installed it in the car before finding that it was too tight. I was assured by 'friends' that it would loosen up, but after trying to start it up, with no success, only a smoking starter motor, I am now in the process of stripping everything down so that I can hone the bores. Like you, I think I need to take out a couple of thou and I am encouraged that you seem to have managed this easily with a honing bar/deglazing tool

Location: About 40 km SW of Limoges

Hi Tony

If I can give you the benefit of my experience, check first of all before honong the bores that the tightness is in that area. I reassembled a 3 bearing engine 40 years ago only to find it was too tight, and altough I managed to get things moving as your 'friends' suggested, the real tightness turned out to be th big engds that wore very rapidly due to some previous 'enthusiast' filing the con rod caps - something that should NEVER be carried out with shell beaings. Honing the bores removes material, and you don't want to increase bore wear unneccessarily do you!

Good luck!

Bob

Location: St Tudy North Cornwall

Hi Tony and Bob.

Tony - the use of a cheap 3-arm hone seems to have worked for me, but as I mentioned, it removed metal a lot faster than some contributors suggested - about 30 seconds to take out a thou - so go carefully, and as Bob says, make sure that it is the bores that are the problem.

Bob - I quite agree about not filing the big ends. I did however pass the mating faces of the rods and caps over a flat, fine oilstone, which revealed and removed a few small burrs. I took care not to remove any material from the actual faces.

I now have three big ends that are a very nice fit on a crank that they didn't start life on. The fourth is going to need a little scraping. Deep breath..............

Location: Herefordshire, with an "E" not a "T".

Martin.

I guess the 4th is a little tight?

Scraping is fun. Do you have the relevant tooling? Its a bit too easy with white metal and very easy to remove too much.

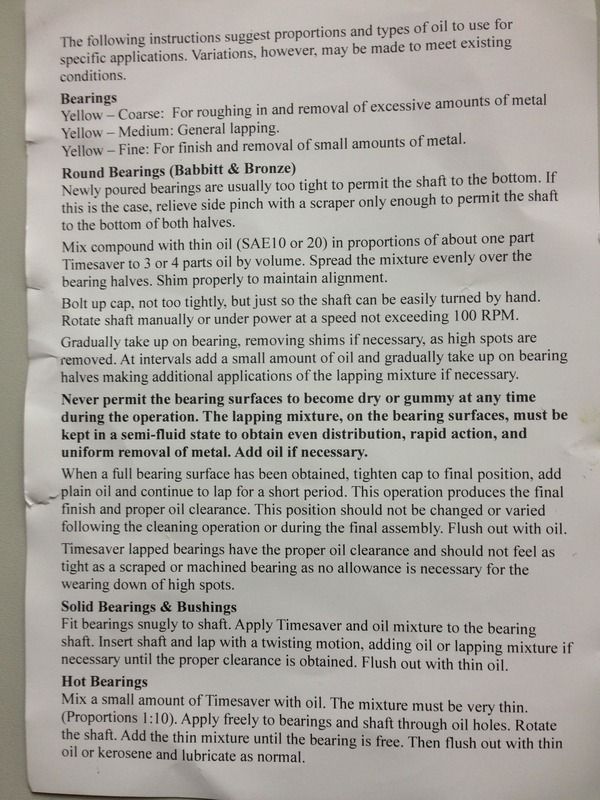

May I suggest you invest in some 'timesaver' lapping compound. It will take the high spots off the white metal but it wears itself out so you dont need to be quite so carefull with cleanliness.

Another product used extensiveley on steamers. Look it up.

Location: not north wales any more

Hi Bob

Thanks for the tip. However my Phoenix crank and matching Austin conrods were supplied by a very well known Austin 7 engine builder and I know that they are OK. Like Martin, I cannot get more than a 2 thou feeler between the piston and the bore. I intend opening this out to 5 thou and see how the pistons slide in the bore.Also, due to inexperience I did not gap the rings. All these good things will be done when I re-build the engine for the second time.

Hedd, thanks for the tip about the Timesaver compound. Appears to be a great product. If my big ends are still a little tight, I will invest in some, probably the fine grade.

Location: About 40 km SW of Limoges

Hi Hedd. Yes, no.4 is too tight. Thanks for the "Timesaver" tip; that sounds just the job, as I know that the amount of white metal that I need to remove is minimal.

Location: Herefordshire, with an "E" not a "T".

In general lapping compounds, other abrasives, and white metal shouldbe kept far apart in case it embeds.

If not shell bearings it is no crime to accurately file caps.

I am much in favour of Martins activities; far more satisfying than just assembling expensive new and reconditioned parts.

But before many others get carried away it needs to be realised that judging from his woodwork efforts Martins abilities and standards are somewhat above the average!

(I have often noted that many of the more enterprising and meticulous restorers have a woodworking background)

When it comes to crankcase cracks a thorough inspection is necessary; the front lip, sides below the studs, cam bearing housing etc.

Whilst piston fit may prove too tight when running, it would be unlikely to render an engine difficult to turn. If that tight the pistons would not enter, except perhaps at the top if bores quite tapered. Big ends or 3rd bearing more suspect. Tales of mechanics towing cars to free them were common into the 1960s but such practices are diabolical. That marvellous fitting in the front with a brass handle has many diagnostic uses.

Location: Auckland, NZ

I agree with Bob about the lapping compound on white metal (it may be OK on harder bearing surfaces). It's an abrasive in a liquid suspension, the particles embed in the soft white metal and continuously lap the crank pin!

I follow Jack French's advice; the conrod should be able to fall under it's own weight when on the pin. If close a judicious tap with a mallet all round can help with the high spots. Being quite small it's hard to scrape the metal out without digging in and putting grooves in. I've a very small 3 sided scraper I use. Try slowly grinding the teeth off a short 3 sided file and sharpen the edges on an oil stone. You have to be patient scraping and not try to dig out too much, the scraper should just take a skin off. You may want to think about belling the ends a few thou as well to cope with crank whip and give plenty end clearance. I've seen big turbine bearings cleaned up with a Scotchbrite pad - the industrial equivalent of the washing up plastic scouring pad, it may be worth a try when you get close.

As Bob says if you over do it take a few thou off the faces and have another go!

Keep us updated.

Dave

Thanks, Dave! Yes, three rods glide down gracefully under their own weight, so I'm quite happy with those. I think that the fourth is a little too tight for the tap-with-a-mallet solution to work, so I'll pool all of the advice that everyone's kindly provided and just go very carefully with the metal removal.

Location: Herefordshire, with an "E" not a "T".

Bob and Dave. Please research the 'Timesaver' it does not embed or continue to lap.

So that when you are reading the guff. The term 'Babbit' is what the Americans term white metal.

Location: not north wales any more

So that when you are reading the guff. The term 'Babbit' is what the Americans term white metal.

I second that on Timesaver.

Not your text book lapping compound so the usual rules do not apply

C

Hi Hedd,

An entirely different possible use for this 'Timesaver Lapping Compound' - I want to gently remove a thin very old (1950's) top layer of paint to reveal the sign written paint layer below, as on a sign written van door. Any thoughts on whether you think this compound may have that desired effect on old paint ? It's probably going to be a case of me buying a tin and giving it a try. I see Craftmaster Steam Supplies sell it for £14.95 for a 3oz tin.

Jeff.

Location: Almost but not quite, the far North East of England

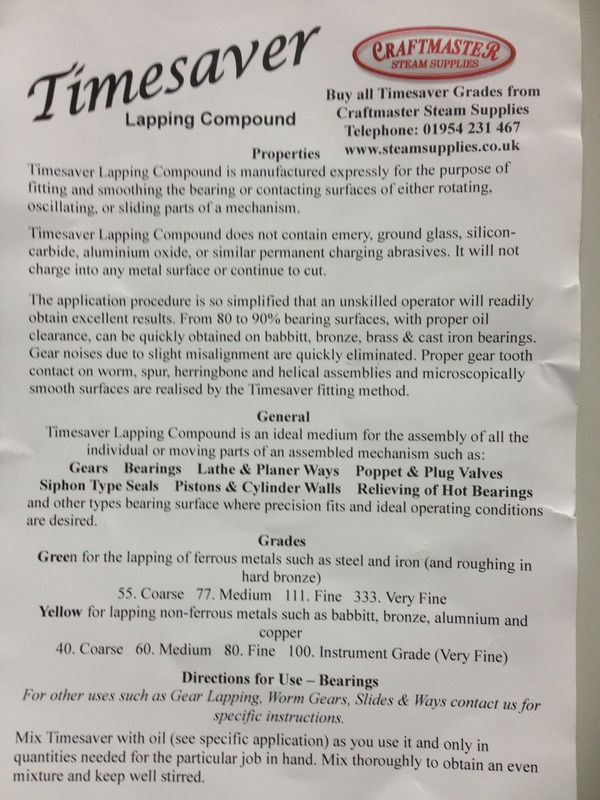

TIMESAVER LAPPING COMPOUNDS

order on line

add to cart

yellow can

PRECISION FINISH ON BEARING SURFACES

GUARANTEED NOT TO IMBED - WILL NOT CONTINUE TO CUT!

Please see Precision Finish Booklet (PDF)

Timesaver Lapping Compound does not contain emery, aluminum oxide, silicon-carbide or similar charging abrasives.

They are unconditionally guaranteed not to imbed into any metal surface.

Prepared in powder form, to be mixed with oil as used.

Timesaver first acts as an abrasive, then the particles diminish to a polish, and finally to inert material.

Directions for use in each can.

.........So hopefully does exactly what it says on the tin.....?

Location: Herefordshire, with an "E" not a "T".

Mine is not in a tin. Its in a plastic box

Location: not north wales any more

Hi Hedd,

Which grade of Timesaver would you suggest for Martin's job - there are 4 listed.

Regards,

Steve V.

Location: Polegate, East Sussex, United Kingdom

Hi Hedd,

Which grade of Timesaver would you suggest for Martin's job - there are 4 listed.

Regards,

Steve V.

I use the medium on bronze and it works out well. But I would be tempted to use the fine on white metal. But its all about how much material you need to remove. If Martins conrod is hellish tight starting with the medium may be an idea.

In anycase the paste gets finer as it is used, to a point where it is almost doing nothing.

Location: not north wales any more

For info. Adam Brown who runs Craftmaster has a ruck of vintage tack. Including a 1930 AE Chummy just like mine.

Location: not north wales any more

Strayed somewhat from bores!

The 1920s idea of fitting b.es. so rods just drop was based on scraped bearings with high spots. If the crankpin unworn all around, it would now be considered too close for precision mated surfaces, given todays trend to hard use.

Applied to cars driven reasonably, belling must greatly reduce life. Close fitted parallel bearings looked fine on my RP held often at 50 mph and 30 mph in 3rd, 35 on occasions. I guess adequate piston side clearance is a factor.

Years ago significant filing of b.e.s and rescraping was regarded as a ritual part of any overhaul. The idea seems to have been to remove the hard abrasive layer which forms without a filter and thus extend crank life. (But in any case, with reasonable oil changes, the wear life of Seven cranks will likely extend beyond their fatigue life!)

I don’t know what standard practice of machinists is, but it would seem prudent to provide slight relief at the parting line, as built into shells.

Location: Auckland, NZ

At the risk of becoming a "cylinder bore" I thought I would share a recent experience.

I am in the process of rebuilding my RP engine. The engine was as it had finished our trip from BA to NYC in 2013. Although it produced a miasma of oil haze in the cabin, it went like stink, but the lubricant inhalation was probably not conducive to good health, so in anticipation of a trip beginning with the 750 Euro Tour to Salzburg and then down the Adriatic coast to Albania, by ferry to Italy and then Spain and home from Santander, it was time to rebuild.

I obtained another block and had it bored to +40, pistons and rings supplied by Jamie at the Seven Workshop. The actual bore size being as required on the ring packet. The advice from Jamie was to gap the rings 3 to 4 thou, however once bored and the rings inserted, the gaps were already 8 to 9 thou. I spoke to Jamie then went back to the machine shop, Guardias engine Services, where the bores were checked for finished size as well as the pistons and rings. The bores were actually a fraction undersize, the pistons exact, it turned out to be the rings that were too small/short.

Having discovered the source of the error I asked both for advice on what to do. Guardias are of the opinion that 9 thou is fine, he suggests 12 on a normal road engine. He has machined Austin 7 race engines with less clearance, but his experience is that it promotes bore and ring wear. Jamie would have replaced the rings if I wanted to try others, however I have settled for the existing items. There are two compression and two oil control rings per bore in split skirt pistons.

I want to emphasize that I have spoken to the supplier and engineer, both of whom were patient and thoughtful in giving their opinion and advice, I have no issue with either. Guardias say that in his experience of dozens of rebored engines each year, the rings are often supplied shorter than required to allow small gaps. Jamie reports that he is supplied by two different manufacturers and passes on their recommendations as to bore size and ring gaps.

I suppose you pays your money and takes your choice! Watch this space,in this instance 0.009".

(Answers on a postcard please to MR R.Dunford, Up North, Beyond the Artic Circle, Kiltshire)

Location: Foggy Cotswolds

There are many ways to skin a cat, my preference is to measure each piston individually and then bore to suit. The rings can then be adjusted, if required, to suit the bore.

The gap you have is not extreme by any means and will most likely serve you well.

p.s. I used to send my Grandmother a postcard from every holiday - another tradition bites the dust!

The ring gaps in my current Chummy engine are 0.010" - 0.012". I didn't build this engine, but a well respected Austin 7 man did. Runs well, with no problems.

Location: Wales

Ruairidh

Where did you find the 2 pages of info on that Timesaver compound.......I would like to do a printout but cant find that info on the company webpage.....also just trying a print of the forum page just wants to print the entire forum subject.

Dennis

It came with the powder when I bought it Dennis.

I will email you a copy of the photos to print out.

At one point it was very difficult to get. Newman tools in the states have all the guff on their website.

I have often been annoyed with replacement rings for other makes. To simplify work for mechanics and avoid comebacks rings were supplied gapped for smallest tolerance bore and gaps are generous on others, esp any honed. For worn engines many ordered rings .010 oversize.

Most textbooks and ring manufacturers recommend at least .003 per inch dia, altho the Seven and other oldies originally much less. Quite large gaps make surprising little difference to performance. The used refit limit for many cars was given as about .030. ACL ,major manufacturers in Oz, quote .005” per inch plus .001 as max for new rings pus another .010 for rehoning and wear. I supect large intial gaps are favoured for modern very slow wearing rings whereas most c.i.rings develop extra gap in first 10 minutes.

Location: Auckland, NZ

Hi Martin and others

My new Moore & Wright digital calipers and my new 3 prong glaze buster/hone have just arrived via Amazon, so have been doing a quick check. Initial results are cylinder bore in block 2.2285" and piston dia below rings at 90 deg to gudgeon pin 2.2285". No wonder my engine was tight. I hasten to add that the block is one that I obtained with the rest of the heap of spares and had already been bored. Not being used to A7 engines, I didn't think to check the bore size, but as it came with a new set of +30 thou pistons, I assumed that it would be OK. Anyway, now have to hone the bores to give the correct clearances.

When searching the internet for a 3 prong hone, I noticed that a couple of suppliers recommended using brake fluid as a lubricant whilst honing. Did you use anything as a lubricant when honing out your block?

Location: About 40 km SW of Limoges

From the sound of it, Tony, you did well to get the pistons in at all!

I used a few drops of light machine oil while honing, but I imagine that brake fluid would be just as good.

Location: Herefordshire, with an "E" not a "T".

I am very surprised, Tony, that you are able to obtain an accurate reading with a digital caliper.

I recently purchase a brand new bore gauge / comparator from Machine-dro.co.uk for around £40. Superb quality for the price, with a range from 2.0" upward.

The obvious usefulness is that it will accurately measure the whole length of a bore, ovality etc.

Chris

Location: Melton Mowbray

Hi Chris

I have a set of locking telescopic spring loaded bore measuring gauges. Basically a T shaped thing, the top of the tee being the spring loaded bit that fits inside the bore and the vertical of the tee being the handle containing a threaded rod that locks the bit that fits in the bore in position. Using this combined with the digital caliper allows the measurement of the bore at various points over the full length. I am sure that your bore gauge will be a bit more accurate but I think that what I have will suffice for now. I will insert a piston without rings in the bore tomorrow and see of I can get a feeler gauge between the piston and the bore and also carry out a more comprehensive survey of the diameter of the bores. Hope this makes sense!!!!!

Location: About 40 km SW of Limoges

This discussion seems to have gone full circle!

I'm with Tony and Renaud.

We've already established that with care, calipers can give an accurate result - mine isn't even digital!

Location: Herefordshire, with an "E" not a "T".

The Instruction for an Ammco surfacing hone is to use copious Ammco oil.

The instructions for a Ritch brand rigid hone state to use kero for finishing, followed by oil and 8 parts kero to polish.

Cutting is most rapid with oscillation as reqd for the cross hatch and with copious liquid.

Another source for a rigid hone reommends viscosity of 7.5 mm mm/sec, however that relates.

Ring manufacturers state that the bores should be scrubbed with soap and water until a white rag stays clean

I had a set of Jowett liners rebored by a practioner who claimed to have a suitable jig. The result was .003 out of round. He said he would refund if I could do better. So I spent a few days adjusting my super crudely made Indian lathe and did a set. I got my money back.

Finished with the Ammco hone with oil in kerosene.

If filing nails is too tedious a primitive version of the telescopic gauge is not hard to make. Working to one meaurement standard reduces errors which can quite easily stack up to .001. Hence the value of the feeler test.

Location: Auckland, NZ

Hi Martin & Renaud

Thanks for the endorsement of my measuring method. Hope I am not being a bore but I have just completed my survey and have found the following:-

All cylinder bores 2.2285" +- 0.0005 i.e. newly bored with minimal ovality or barrelling.

Piston - Top dia at piston ring location - 2.218"

Skirt dia parallel with gudgeon pin - 2.223"

Skirt dia 90 deg to gudgeon pin - 2.228"

i.e the skirt has 5 thou ovality

With the piston in the bore, there is absolutely no rock at 90 deg to the gudgeon pin but rock due to the 5 thou clearance in the plane of the gudgeon pin.

My question is, should there be between 4 and 5 thou clearance between the piston skirt and the bore at 90 deg to the gudgeon pin? i.e do I hone out the bores by 4 to 5 thou to give this clearance? Also, honing out the bores will increase the ring gap to at least 15 thou ( 5 thou x 3.142). Existing ring gaps between 10 and 13 thou (as supplied with the pistons)

All urgent responses will be much appreciated as I wont start honing until this is clarified to my satisfaction.

Location: About 40 km SW of Limoges

Tony, suggest you read all the posts in detail from the beginning.

Can readily detect .0002 difference in bore size with telescopic gauge or fitted nails, but accurately transferring and establishing the absolute length is tricky.

Feeler clearance is the ultimate test (assuming thin)

The side clearance is important; the piston expands more in that direction, and there is no give. And it helps accommodates crank flexing.

I do not know the recommended clearance for split skirt supplied when new but probably not more than .0015 with a feeler. Even a true .0005 should not be very tight to hand crank

.005 is racing clearance for a solid skirt piston.

The pistons must oscillate freely on the gudgeon after it is clamped.

Location: Auckland, NZ

HI Tony,

If you have split skirt Pistons those Sizes are spot on

if solid will need an xtra .0015

Hope That Helps Colin

Location: TINOPAI NZ

So another weekend of dodgy engine building comes to an end.

Just to make things clear, this is typical of the quality of scrap that I'm working with..............

This particular engine has donated its pistons, which have cleaned up surprisingly well, and is going to provide a matched pair of timing gears.

I ordered a tub of Timesaver Lapping Compound, which arrived the following morning. I'm very impressed; it only took a few minutes to ease the very stiff big end, so I gave the others, which were still a bit lumpy, a light application, with very satisfactory results.

As I still had some mixed Timesaver - which isn't cheap! - I decided to lap the flywheel (from a sixth engine) to the crankshaft with it and cleaned up the taper very nicely.

I struggled a bit finding a serviceable set of correct main bearings. Most of them appeared to have been buried for several decades and were seized solid. normal attempts at cleaning failed miserably. I eventually resorted to holding the inner race in the lathe (1913 Drummond "B"), while holding the outer race with a bit of wood and flushing with paraffin and oil. Most of the muck went up the workshop wall, but it worked and the bearings now run smoothly.

Location: Herefordshire, with an "E" not a "T".

Great stuff Martin. Your posts have inspired me to buy even more A7 junk at a recent auction to mix with my own pile that has been festering under the bench in the hope of creating something that can rattle out a good few hundred miles!

Unless the goo was just dried preservative grease, I am not sure that the resurrected races will be a success.

I dunno about mains but in most other auto applications any roughness is apparent. All rolling race surfaces need to be perfect for smooth running.

Almost any clearance wear in the roller bearings leads to rumble.

Parts from slightly worn roller races can sometimes be mixed to achieve a very close clearance, but can be hard to assemble. The a.c races can be shimmed but overdoing threatens the lip.

Both with Austins and others it always troubles me the way so many parts are ruined by rust and corrosion. Once any bearing surface is corroded it is rendered largely unfit for serious mileage. Parts reusable by the patient are rendered useless. And rebores, regrinds etc are unnecessarily triggered. Parts need to be preserved in grease; oil soon dries off.

Love Martins lathe with useful apron platform. Can it be accurately dated? Straight out of my fathers 1920s Model Engineer mags. Was it originally round belt drive? From a treadle? I wonder how many modern equivalents with diecast and nylon gears, fancy belts etc will be around in 90 years. The oil can also a museum piece.

I like what appear to be copper vice clamps. A device unknown to most commercial “mechanics”. It is what old h.w. cyls are for.

In most of the commercial garage workshops I have been able to explore, not even sheet steel clamps are to be seen anywhere. Nearly every

Seven dynamo shaft sports vice marks on the bearing journals.

Location: Auckland, NZ