Welcome to the Austin Seven Friends web site and forum

As announced earlier, this forum with it's respective web address will go offline within the next days!

Please follow the link to our new forum

http://www.austinsevenfriends.co.uk/forum

and make sure, you readjust your link button to the new address!

Is your half shaft perfectly straight?

That I am not sure of I would have to strip again

Location: Burntwood staffs

Alternatively it may be that the hub outer has ben distorted or badly lapped in the past causing it to run out of true. I have also experienced some questionable, probably Chinese made bearings, I always try to use known reputable bearing brands.

Location: NZ

I have tried two different bearings but no different!!!

Could be that the axle casing isn't straight; the wheel bearing will have a constant load on it if this fault exists. I've had to straighten a couple of A7 casings in the past.

A quick check is whether the halfshaft can be made to touch the top, bottom, front and rear of the inside of the axle tube with the same amount of resistance when you have the hub removed. if there is noticeably more resistance at any one point while you're moving the shaft up down etc. You either have a bent halfshaft (which would have been noticeable because of the wheel wobble when driving) or a bent axle casing.

Location: N W Kent

Hi Trevor

What do you mean by play? Tilt, end float, or lift?

In this application the bearing need not and should not be a close fitting type; it must allow some tilt due deflections. Assuming the bearing is not very close fit, tilt is determined by the axle fit at the diff end. If bearing a very close fit, inclined to loosen in housings.

Unless operating in sand or water, ball races do not develop significant play unless failed with the track spalled, unliekly with the very adequate Seven bearing.

It seems most likely the race is working loose on the axle or in the hub (neither of which condition, and esp the hub, much matter provided the retaining nut remains secure)

All the suggested defects will encourage a race to loosen in housings.

(If reliant on sealed bearings these do need to be a good fit in housings)

Location: Auckland, NZ

Hi

If the axle shaft is loose or worn where it Rotates in the differential carrier it will put severe loads on the wheel bearing at the other end as it relies on a close fit here to support the shaft from flailing about.Single row ball races are not designed for such loads- unlike a full floating axle arrangement where the axle only transmits torque.

It could be that the axle is a small dia. one in a large diameter bush in the carrier, as there are two different sizes -the variation is 1/64" from memory. I have come across this on several occasions.

if this is indeed the case the Bronze bushes supporting the axles in the differential will be hammered out and need replacing which entails a full strip down to extract the shafts.

I feel this could be the cause of your problem.

Cheers Steve H

Location: Wellington NZ

After looking at it again, yes I would say that th movement si at the dif end so going to be that bush,

Thanks for your advice.

Regards trevor

Location: Burntwood staffs

Whilst on the topic, the Seven rear wheel bearings are very adequate for the car weight. Provided the tracks and balls are free of pits or spalls, generous shake and clearance is of no consequence. With old cars everything is likely somewhat out of kilter and a slack race accommodates, and is preferable to a close fit new standard tolerance bearing. For semi floating axles, effectively the same situation, NSK recommend a C5 bearing, with 2-3X the internal clearance of a standard bearing.

Location: Auckland, NZ

Could be that the axle casing isn't straight; the wheel bearing will have a constant load on it if this fault exists. I've had to straighten a couple of A7 casings in the past.

Stuart. Could you explain how you straighten the casting please. Sounds tricky to me.!

Location: Derby

Could be that the axle casing isn't straight; the wheel bearing will have a constant load on it if this fault exists. I've had to straighten a couple of A7 casings in the past.

Stuart. Could you explain how you straighten the casting please. Sounds tricky to me.!

Hi Ray,

I have done two A7 casings in the past as I said. but, s*ds law; I don't have photos of them.

However, I have done loads of "other" axle casings over the years, for which I do have photos -the process is the same, so I hope you'll forgive.

First up, from a 750 formula car. brand new rear wheel bearing on one side was knackered after six or so races. The bright red spot in this photo is where the halfshaft would point -there's a laser shining up the axle tube- the dull red blob of paint is the diff centreline where it should be pointing. I used a laser on this because the BMC "A" series axle has tapered tubes and a "drop out" style diff, which makes seeing where the fitted halfshaft should be pointing rather tricky.

BTW, the laser technology I use for this is rather more pound shop than James Bond. Here it is, the beam is dead centred using the three grub screws -only two are visible in the photo.

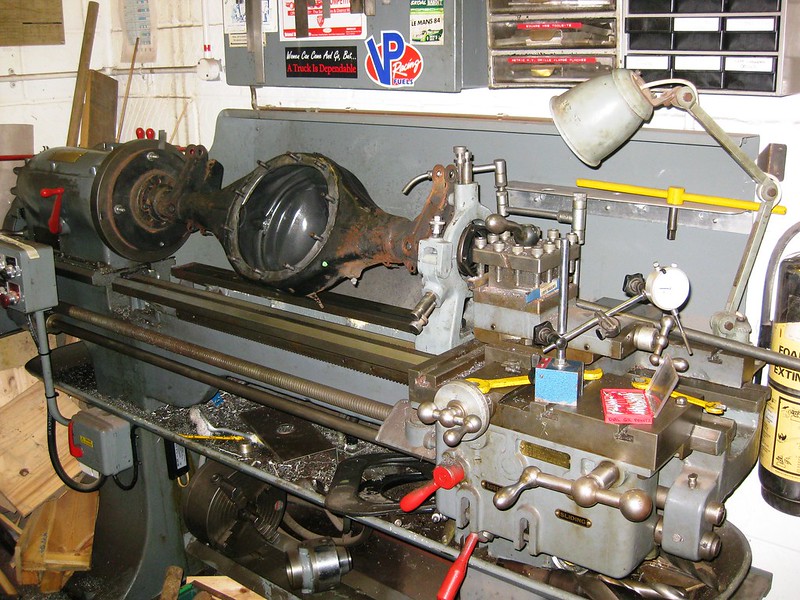

Almost all the axles I have straightened use the rig in the photo below. The machine jack 'bends the axle straight' The axle is given the dullest spot of red heat from an oxy acetylene torch opposite where the jack is pressing.

The next shot is of a failed wheel bearing from an American Ford axle. This axle had been professionally built at huge expense. Unfortunately, the car's owner had never got more than 200 miles from the rear wheel bearing on one side. He replaced several before he would be persuaded that the problem wasn't actually with the bearing.

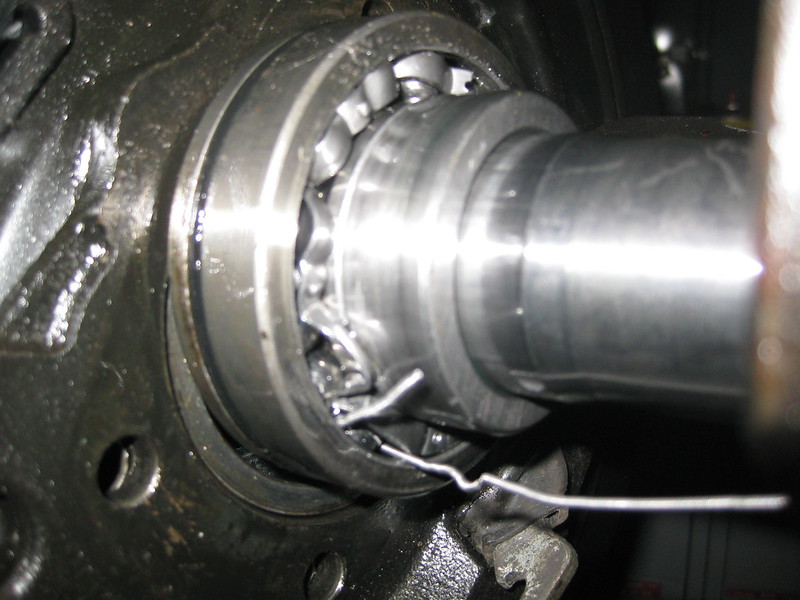

I assembled the halfshafts in the axle with machined from billet dummy wheel bearings. Here's the halfshaft alignment.

Maybe not too relevant to the A7 world, but sometimes re-working the axle tube(s) isn't really an option. This particular axle was/is incredibly narrow, (the car is intended for occasional dragstrip duty, so has wheels/tyres around 15" wide) with suspension brackets welded all over the axle casing. On this one I put the whole axle into my "big" lathe and machined the wheel bearing seating so that the halfshaft pointed at the centreline of the diff. The car has done several thousand miles since with the same wheel bearings installed.

A7 axle tubes aren't very thick, so a good whack to the kerb at sometime in the past is probably all that was needed to bend a halfshaft and /or the casing. On one of these I straightened that was probably the cause. The other A7 casing came with telescopic shock absorber brackets stick welded on, and the welder had obviously turned the current up to make sure of a good strong joint. Unfortunately, the resulting weld shrinkage/distortion had pulled the axle tubes out of true. This axle was straightened in the normal way. Once the axle is split and the halfshafts released from the diff, removing all the inner bearing and oil seal hardware before re-installing the halfshaft on the hub with an as new bearing will tell you straight away whether the halfshaft is pointing towards the diff centreline as it should be centred in the axle tube at the diff end, it will be pretty obvious if the shaft is off to one side in the hole.

Location: N W Kent

Many thanks for that Stuart. I am sure this will impress others on here as much as it has me. I really appreciate your sharing what is obviously "advanced level" Austin Seven repair work and has inspired me to tackle what would be a new area of mechanics. Fortunately, I have a fine example of standard Austin Seven with my Swallow but should the need arise I will not now feel it beyond me to take on straightening a rear axle.

Location: Derby