Welcome to the Austin Seven Friends web site and forum

As announced earlier, this forum with it's respective web address will go offline within the next days!

Please follow the link to our new forum

http://www.austinsevenfriends.co.uk/forum

and make sure, you readjust your link button to the new address!

I've started bashing metal to make a couple of structural members for my car so that I have somewhere to hang the steering column off of. I routered out this shape in a block of hardwood, got some 1.5mm 1050 grade ali, cut it about 1cm larger in all directions, annealed it, bashed the edges over, shrank the corners to 90 degrees and then bashed the little reinforcing 'domes' to help keep it from warping under load. One down , three to go, unless I decide to modify the shape. Next I'll need to extend the bottom legs to suit the dashboard height and then make sections to go between these bits shown above.

Probably not the simplest way to do it and no doubt it won't be a patch on a 'proper' one (Roach/Jansen/Yates etc) but it will give me an introduction to methods of design.

Bloody good fun!

Location: Just west of Cardiff

Rob a brilliant bit of metal bashing. Will you be ally welding into position?

Location: Piddle valley, Dorchester.

Thanks!

I'll be Tig welding it together plus some exposed rivets, if I can find a suitably long rivet 'set'.

If anyone has some 'inspiration' pics then I'd be very grateful since I suspect that I'm taking a walk down a path that has been well travelled before, if you see what I mean.

hfh200 @ hotmail.co.uk

Location: Just west of Cardiff

I'll be Tig welding it together plus some exposed rivets, if I can find a suitably long rivet 'set'.

If anyone has some 'inspiration' pics then I'd be very grateful since I suspect that I'm taking a walk down a path that has been well travelled before, if you see what I mean.

hfh200 @ hotmail.co.uk

If you are using a traditional set, there's no reason why you could not make an extension from a length of 25mm bar, drilled to accept the snap and held in place with a couple of grub screws, a bit cumbersome, but it may get you out if trouble, at least you can give it a good welt without fear of breaking it..... BTW Nice bit of bashing

Location: sarf coast

I've started again, with some assistance (hindrance?) from the kids. The new rear springs, acquired via John Williams in Porthcawl, have worked well and the car now sits about 6 inches lower at the rear than it did on the old set. Ideally I'd like to lose 2 inches from the front to get it level without needing to worry about a 'dropped' front axle beam.

I'm making it a semi-monocoque structure on top of a plywood floor so as to allow a bit of flexing without cracking the ali.

There are a couple of questions that I'd like to ask. Firstly, how much does the rear axle shift sideways, if at all? I've allowed 1.5 inches between the inside face of the rear tyre and the outside of the skin of the inner wheelarch (not shown in the photo). Secondly, do the Ruby fuel tank and chassis extensions need to be left floating or should they be tied in to the body? Is it necessary to keep the ends of the fuel tank from any flexing or is that a natural effect of the floppy chassis? Has anyone heard of a tank being damaged by being left to do its' own thing?

Many thanks

Rob, near Cardiff.

Thanks, Ian.

I have an 'almost flat' front spring here but it would leave less than 2 inches betwixt spring U-bolts and the axle beam. Not enough?

Thanks gain, Ian.

I\'ll give it a try. If it doesn\'t work then I know where to come for the necessary bits.

Meanwhile, the bulkhead sides are finished and the firewall skinned. I still need to work out a profile for the in-fill between the side pieces and that will affect the shape of the dashboard since it will need to be the same shape as the first bulkhead at the top. I'm tempted to ditch the idea of solid sides (Ulsteroid style)and to fit doors to it now that I'm likely to have to go into hospital soon for some spinal surgery. If I make the dashboard bulkhead soild enough I should be able to hang doors from it rather than hinging them at the back.

Does anyone have some 'inspirational' photos of door hinge mechanisms that I could look at? I'm assuming that the hinge is best if it protrudes out from the bodywork and the pillar is reinforced with wood?

PS. Thanks for the footwell measurements, John. That template worked out very well!

So, I've made some side pieces and intend to put a couple of 1.5 inch square posts on the outside of the rear edge to act as hinge pillars and to give something for the ends of the dashboard to sit upon. Should it be Ash or would Oak do the job?

The hardest job will be skinning the outside of this lot, especially at the rear where 1/2 of the tyre will be inside the body, necessitating some crafty fabrication like the back of an MG PA body. I have managed to make the footwell just big enough so that I can get the throttle pedal alongside the brake without my size 11 shoes touching both at the same time. Might also be worth putting a small bulge in the side of that footwell, just in case.

Could some kind soul show me how the Ruby throttle pedal sits in the standard car? I have no assembly to work from, nor do I know whereabouts it normally enters into the footwell. Thanks.

Ash ordered today for the door hinge assembly and all the pop rivets have been replaced with proper slotted dome-head setscrews. I took the opportunity to wheel an extra inch of space for the right foot before putting the side panels back onto the footwell. Correct tyres for the front should be here by next Monday. Hopefully I will then be able to go for a drive round the garden.

Rob, Phil who supplied us with the rear springs has a couple of flat fronts available. If you want them, I will pick them up at the next club night for your inspection. John

Location: porthcawl

Rob,

Post your email and I will send a pic

John. Thanks for the offer but I think I'm sorted. I've salvaged a flat front spring that only had 3 leaves and added the extra ones from the existing set. It now sits nicely with 3 inches of 'drop' available and it looks right (which is what it needed) after I lathed up some new bushes in the spring eyes. The hardest part was getting the centre bolt right through the stack of leaves!

Thankyou Derek. I'm at hfh200@Hotmail.co.uk. I assume that the original sits on the front of the bulkhead and pivots from the top?

I found a Morris 100 throttle pedal and decided to see if I could use it. The lever on the carb ran the wrong way but with a bit of lathe work I made it work correctly. It runs on 12 volts at the moment but I've found boxes containing 12 and 6 volt regulators etc and will need to decide which way to go. Probably best to start with 6, so long as I can work out the wiring. Which regulator usually goes on an ARQ? I have CF1s all the way through to RF95s. I Googled for photos of the wiring into the back of the switch and regulator. This bit will need some more thinking so that I don't screw it up!

It took a bit of effort to form the top of the engine bay bulkhead and it has given me more back ache but I think it is almost finished apart from skinning the outside of the front half of the car, a job to save for last. When I shortened the exhaust manifold I took the chance to run the exhaust pipework inside the floor area and through a small formed hole below the door hinge area. Next week I should be in a position to ali weld the top piece of the bulkhead to the sides and then get out the Scotchbrite and the polish.

This is a lovely thread!

I built a Special a few years ago (not yet 100% finished) and I made my own acc-pedal from an aluminium bar pivoting from the top in the bulk head. I made a rod connected to the carb spindle by using very simple means, a threaded bar (M6) and it all connects with rod end- rose joints.

After exploring the length needed I calculated the stroke of the pedal and used the gearbox as a pedal bump stop. (Mind it's a left hand drive model, so the acc-pedal is actually next to the gearbox.)

I'd gladly post some pics of my build but not sure how to. Will look into this!

Thanks, Henrik.

I tried to work out if I could use a rod but I thought I'd have to make the throttle pedal sit well below the brake pedal rather than in line with it. Using a cable I have got all 3 pedals to line up. From the photos I've seen it looks like the original car had the throttle pedal sitting closer to the ground than the other 2.

If you find any photos, I'm at hfh200@hotmail.co.uk.

Thanks.

Rob

So, hopefully it works.

The body was made up from 4 sheets of aluminium 2x1m. (1,2mm) The sides are sandwiched two sheets with square ali-profiles, very rigid! The floor and bulkhead were a 3mm thick aluminium sheet. The split between rear and front is deliberate, to prevent it from cracking.

It's actually glued down with a "space glue" into quite hack sawed pieces of thick hardbord-plywood profiles. No visible wood profiles nor rivets except in the engine bay.

Entire body weighs less than 20kg.

Dashboard is a 1/2 inch solid walnut board.

The paint is cellulose 12 layer with wet sanding between.

Your body is so very much more tidy than mine in details, when I see it I regret not being "smarter". If you have any thoughts about details, please let me know and I can email better detailed pics.

Here you can see the spindle and rod for the carb.

Thanks Henrik.

The throttle pedal looks easier to work out for the left hand drive cars but the clutch pedal looks weird!

Yesterday I bought some Ash wood to make the sides and the pillar for hanging the door from. It is bolted to the metal rails along the side and will also hold the dashboard in place. I might try to make a aluminium dash and then make those nice swirl patterns (Machine turned???).

It looks really really good Rob, ash is the way to go, oak contains some kind of acid that kills the screws.

Not sure about the metal swirl thing as I think it might be tricky to get it evenly, but give it a go. Please keep posting updates!

Location: Sweden

Thanks, Henrik. I've got a supply of Ash now, so I should be alright.

Top of the dashboard cut, folded, wired and drilled. Lots of opportunities to screw it up but it seems to have worked. Only major problem is that somehow it has grown by 1/4 inch on one side. How???? Oh well. It will have to do. Not sure if I should use solid 1/8 inch rivets or pops but those Cleco clips are working well enough for now.

I was thinking about the doors and fortunately some handy photos have just been posted on another thread. They don't look tooooo complicated (in theory only!) although mine will need to taper from front to back. Some more Ash will be needed. Hinges are also a problem so I might need to buy some brass sheet to form some.

Any suggestions would be gratefully received. I only have 3 weeks left to go before it needs to be finished.

Ta

Rob

Rob,

Is the surgery really necessary?

I ask, because a friend who was a single figure handicap golfer, had to stop playing as he was suffering from increasing back problems, and advised that surgery was needed.

That was in the '60s when back operations where more prone to cause problems than heal.

At the time both Mother and I used one of those back stretching machines, as we suffered back problems.

The machine we had, and I still have, consists of two A-frames with a tilting support board attached.

You stand on said board, clamp your ankles, rest your back against it then swivel backwards until you are near vertical head down. The 'modern' iteration of this machine doesn't instill any confidence, as they don't have any framework to hold onto when tilting.

Mom told our friend to borrow the machine and try it out, and in desperation he did.

Well, a month later he was back swinging his clubs, and without so much as a twinge.

The surgeon/doctor couldn't believe it, BUT it had saved him from unessesary surgery.

It certainly helped Mom and I, and continues to do so for me, but far less frequently now.

Geoff - Practiced sewing leather yesterday, using the Singer machine.

Edit:

Very remiss of me not to say well done so far!

Location: South Norfolk - Next to Suffolk

Thanks Geoff.

Yes, sadly, it is going to be necessary since the 3 broken vertebrae are slowly drifting apart like some sort of 'Continental Drift'. I've also lost the feeling in my right foot which is a no-go as an airline pilot. No Op...no job. The MRI scan shows everything nicely and you can see the rear half of one vertebra clearly separated and the associated discs bulging and impinging on the nerves to my leg.

I've got a Singer sewing machine as well! I haven't used it for maybe a year (Sewing a new bag for my Lee Enfield) but it will be out soon to make a tidy liner for my glovebox. I fitted a dashboard blank with a cubby hole that has been covered with Royal Blue vinyl just to give me something to inspire. I 'wired' the edge of the dash yesterday which was something I could do whilst sitting down to rest my back. The previous day had given me awful aches. Knackered at age 44!

Best of luck with the surgery and a speedy recovery Rob!

How on earth did you break them? Ouch!!

I have a Singer 660 A1 industrial machine, that I had to dismantle to get home.

The first time I tried it, after its rejuvenation, it just took off speed wise having a Seven type clutch, so totally unsuitable for my needs.

Got the speed down by replacing motor pulley and then experimenting with the clutch lever compression spring, and with additional expansion springs, last week managed to get the beast to behave in a more civilised manner.

I now have full control of the speed and can now start at a crawl and build speed as I wish, although I doubt I will ever be able to handle the thing at full tilt. Hats off to those in industry who did/do.

Geoff - Where/how did Williams find Bottas. Good to see them back on form at last!

Location: South Norfolk - Next to Suffolk

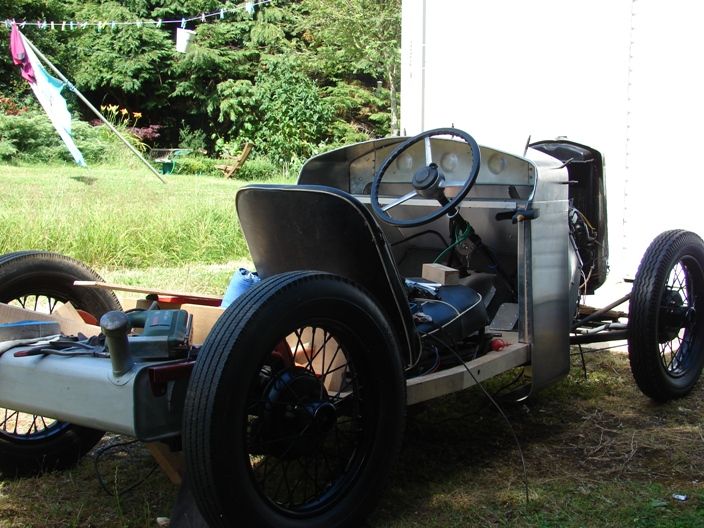

First run along the garden and up the driveway. First wheelspin, too!

The side covers are riveted at the front and welded where they fold through maybe 10 degrees to follow the shape of the car. I haven't worked out how to make the rear arches yet. Any suggestions?

Thanks Renaud. There are 2 breaks at both door posts so I hope it will be alright. Tyres are 4.50x17 rear and 4.00x17 front. I've also got some 14 inch wheels but they are too small.

For some reason it has decided to make a nasty metallic squeak/howl when the steering is turned and then to go very stiff. I've slackened the adjuster screw off and slackened the 3 cover bolts right off but it remains there but only when there is weight on the wheels. Dry bush on the output arm of the box? I can't get underneath to play with it any further.

Rather than having a boring end to the exhaust pipe I hammered a recess, cut a hole and ran the pipework back outside the body tub. Looks better.

It would look good pulling an Airstream Caravan!

Thanks, Leon.

You must have spent a bit more time on research before you started. I'm now finding that it would have saved a lot of effort if I had spent more time thinking through where the doors were going to be and what shape to make for the edges of them. I wanted it to be wide enough to fit my size 11 feet but the side effect is to make the body so wide that I need some rear wings in place before I can think any more about rear body shape. Running out of time! I've spent about 6 weeks on it so far from the bare rolling chassis stage but next time will be quicker.

Oh, and the squeak from the top of the steering column turned out to be the mis-shapen ball and socket on the axle end of the steering rod where the joint was dry. The sound travelled a long way! That wasted a couple of hours.

Leon. If you have any photos of the body/build then I'd be very grateful if you could show me, possibly via an e-mail?

Thanks

Rob.

hfh200 @ Hotmail.co.uk

Rob

I've been thinking of what to do with it since I got the car, but it's not been plain sailing. You can see that their are lots of unfinished projects about.

We've been working on the rebodying since January putting in about 8 hours per weekend, only got the bonnet, wings and bit for my right foot to go.

Location: Suffolk, just

renaud

It's not been easy, if you click on the pic it should take you to my Photobucket and most of re build are on it.

The frame work seem to take ages, and the double curve panel needed more skill than we've got, so we had to try the fabrication route.

Location: Suffolk, just

renaud

It's not been easy, if you click on the pic it should take you to my Photobucket and most of re build are on it.

The frame work seem to take ages, and the double curve panel needed more skill than we've got, so we had to try the fabrication route.

Location: Suffolk, just

My friend doing his first sprint at Goodwood next month has some build videos on YouTube. This is the introduction. There's one on making doors, another on the dash and a couple of general updates along the way.

http://www.youtube.com/watch?v=JuuRnY01ulw&list=UUJrbFfWquVY--I8luse-oLw

David

Location: Lewisham, London.

Thanks, David. I've seen those before. Nice woodwork but I don't have the equipment to cut wood like that, only metalworking stuff and a few saws.

Anyway, I made the bonnet hinges and then the bonnet tos. I noticed that the bonnet 'hole' tends to 'lozenge' when the car goes over bumps, adjusting the shape and dimensions of the hole. Presumably this is a natural effect of a flexible chassis? How much gap should I leave between the bonnet skins and the bulkhead/Radiator cowl? I cut it so that there was just a 1mm gap but that seems waaaay too optimistic. What sort of gap is there on a Chummy bonnet to allow for lozenging?

If I were to sit on the passenger side then the rear edge of the bonnet at the lower end will move away from the scuttle by about 8mm and obviously will scratch the rad cowl by the same amount. The same will no doubt happen if the car went over a bump so I'm stuffed at the moment

What is the situation with the normal car or with Ulster replicas? Any photos or personal experiences???

Thanks

'Desperate' of South Glamorgan.

Hi Rob,

I'm enjoying your updates. Keep them coming. You're doing a great job.

When I made a bonnet, I overlapped the scuttle, by about an inch. It used to move all over the place as I drove along a grassy field, but I think it meant that it wasn't trying to push the radiator cowl around so much.

I hope you find a better solution than this, as I'd hate to think of you having to make another bonnet.

Good luck,

Colin

Location: Towcester

Rob,

Your bonnet top is quite deep sided which perhaps may magnify chassis movement.8mm still sounds far too much. Is the body to chassis mounting not fastened tightly or is it too weak? My pretend Ulster does flex about half that I would guess. The bonnet side panels on it are attached to rad and to scuttle by bolts and 20mm washers at the top corners of the panel with a rubber washer to stop metal to metal contact and works fine.The holes in the side panels for the bolts are slotted. You can hear the slight squeaking of the rubber when going over large bumps. Also are you intending to fit the rubber bonnet moulding as the pre-Ruby models which would disguise inaccuracy in the bonnet/scuttle bonnet/rad joint as the bonnet is able to dig into the curved exposed section of the moulding? Having said all this I don't think the chummy bonnets ever seem to fit accurately.I had to chop a small triangle of metal off my chummy bonnet and weld it on the other end. Anyway your car is coming along nicely,

Cheers,

Dave.

Location: Sheffield, the home of Hendersons Relish.

Thanks for the timely replies, Colin and Dave. I'm not great at internet etiquette so wasn't sure if I was posting too much or if these pictures end up getting in the way of something. Having them on Photobucket is alright, isn't it?

As for the body, I was advised to keep the tub from taking big loads by having it suspended from the chassis in a manner that would allow it to remain rigid whilst the chassis flexed. Was that wrong? (Gulp!) I can't imagine a standard early car is much more rigid so it might just be down to cutting the bonnet gaps that bit more wide and maybe employing that good idea about keeping the side panels 'loose', Dave.

What do these rubber bits look like? I've never owned a 7 before and have only every had a single ride in one so my entire knowledge of them is from books and Google.

Rob, I have been watching your thread with interest and see you have a problem that may not turn out to be as bad when the rest of the cockpit is completed.

A standard Chummy does not suffer any problems with the bonnet moving. My bonnet is a good tight fit between the bonnet rubbers and has never shown any movement marking. If I put a finger on the joint where the back of the bonnet touches the scuttle and give the windscreen pillar a good shove there is absolutely no detectable movement.

On a Chummy the scuttle, bulkhead, petrol tank and dashboard effectively form a box, remove any one of these and you ‘would’ find some movement such as you have.

It’s a bit of a job to imagine your finished body from the photos, but I would study the finished design and work out if you will have a boxing effect such as the standard car.

Think of a shoebox with no lid and twist it, put the lid on and it will not twist, it needs that principle in the design I would imagine (I have never built a special and take my hat off to those that do). If you are having a dashboard maybe you could have a full width panel at the bottom of the dash going forward to the bulkhead (leaving a detachable but securely fixed access panel for the instruments). I would imagine that with the movement you have at present is not eliminated the body would soon suffer. All the best Ian M

Location: Bristol UK

Rob,

As mentioned above I think that you will find that completing the body structure and fitting the radiator support valances will help matters, the radiator would move slightly with the body flex. It would probably be an idea to finalize the design and shape of the remainder of the body, cardboard and ply are useful for mocking this up and ensuring everything fit's prior to committing to metal. The Bonnet would normally be one of the last parts that you would fit when building a body. Try to study how other cars similar to what you want from your design are constructed, doors weaken the tub so look at what Austin did on the Nippy and Speedy; Double skinned support valances incorporated into the bulkhead scuttle assy etc. Even so the door latches still held the two ends together to some extent.

Location: NZ

My car is made of little more than tin foil, it flexes a lot and I ended up with a wide overlap of the bonnet over the scuttle. At first I braced the middle of the radiator with a pair of alloy tubes from the top corners of the scuttle to the middle of the rad. The rad split so I removed one of the links. It feels weak grabbing the the rad shell and wobbles like a jelly jacked up. When I get back to working on it (its been off the road 15 years) I've various ideas to stiffen it up.

Trevor's car is built of plate and bolts. He has the standard "cow horns" and I think Ruby steel panels from the rad shell back to the scuttle below the bonnet sides (are these "valances"?). The front is amazingly stiff with the wheels on the ground. It remains stiff with a jack under the middle of the front axle. His bonnet fits tight to the rubber and has had no problems over London pot holes and speed humps and up and down kerbs. His first tip to my godson building up his special was to get cow horns and steel valances (if that's what they're called) and build round them.

Mine has a boxed chassis but the engine "loose". Trevor has a standard chassis and standard engine mounts so its absolutely these panels and the cow horns doing it for him. I'm fascinated that Austin put twin skin sections in there. Anyone got some photos?

Something I've seen on racers is a tie from the back of the cylinder head to the scuttle.

Which Lotus had tubes over the engine?

David

Location: Lewisham, London.

Rob, I am having trouble with both Photobucket and Captcha,hence half a photo!If you click on the image,you can see the bonnet side panel has a chromed screw with a 20mm dia steel washer brazed onto it. Behind the washer is a rubber washer 20mm dia which is trapped between steel washer and bonnet side panel through a slotted hole in the side panel.The screw/steel washer/rubber washer is screwed to the bulkhead using a steel nut welded to another steel washer which is then riveted to the bulkhead.It would be easier to understand if you looked through my Photobucket library where you can see a side elevation of the car and somewhere in the library is a view with the bonnet side removed and the steel nut/washer riveted to the bulkhead.

Dave.

Location: Sheffield, the home of Hendersons Relish.

If making your own then a curve under the bottom edge is going to help. I think they also have a joddle to go under the bonnet edge which will give some strength.

Mounting mudguards have an enclosed hole not a slot through an edge.

My favourite "structures" demo is a card tube from a kitchen roll or toilet roll. Try twisting it, then cut down the length and try again. You'll understand box sections after that. Another one to try is to flap a bit of A4 about, then fold into a "V", then try a "W".

My priority (25 years ago) was weight. Having suffered patter in high speed cornering (one wheel comes off the ground then down then the other up and then down at approx half second intervals) I'm thinking again.

David

Location: Lewisham, London.

http://www.asciimation.co.nz/austin7/?p=354

http://pub25.bravenet.com/forum/static/show.php?usernum=2099944454&frmid=5&msgid=919161&cmd=show

I look at those cow horns and remember the weight - they are mighty bits of metal.

Location: Lewisham, London.

Hmmmm. Last night I re-read the little green book, especially the bit about building 'Simplicity. Tying up with the notes above I wonder if I might be well served by slackening the rad shell from the chassis nose-piece and instead tying it to the scuttle area. The whole body tub is very, very rigid but is slightly separated from the chassis rails by having all the body/floor and floor/chassis bolts spaced apart to allow the ply a small amount of flex. The rad shell, by comparison, is bolted to a 12-inch steel angle that is also bolted to the nose piece. 'Simplicity' is said to have the rad shell loosely fitted to the nose piece by a simple rubber 'washer' and then tied to the top of the scuttle area, thus allowing the rad shell to move in harmony with the body instead of with the chassis (as also mentioned above). There is much logic in there!

On the standard pre-Ruby, how is the rad shell fixed to the chassis? Is it tied solidly to the nose piece casting or does it hang from the body somehow?

Below is a pic that shows the angle iron that ties the rad shell SOLIDLY to the nose piece. Bin it in favour of something more squidgy???

All the early cowls and associated radiators are firmly held with bolts in a short extension of the two flitch plates which in turn are bolted to the two 'cow horns' which are bolted rigidly to either side of the chassis nosepiece (except in the very early cars where the 'cowhorn' is in one piece).

Tony

Location: Malvern, Melbourne, Australia