Welcome to the Austin Seven Friends web site and forum

As announced earlier, this forum with it's respective web address will go offline within the next days!

Please follow the link to our new forum

http://www.austinsevenfriends.co.uk/forum

and make sure, you readjust your link button to the new address!

Does anyone know of someone who can shrink axle eyes?

I have a Cambridge independant suspension set up, and one side has a large axle eye., even with an oversize pin.

Unfortunately, Ian Dunford cannot do this at present!

Many Thanks,

Clive.

Location: Wolverhampton

Hi Clive,

Thinking out the box, I wonder if either of these two companies which are in your general area, might be able to help / advise. If not, a local Blacksmith might be able to shrink the axle eye for you. I remember the BBC TWO series 'Restoration' a few years back featuring a wonderful Blacksmith's shop - I believe it was in a West Midlands village - I think it got the restoration funding to continue as a working / training centre for Blacksmithing.

http://www.brooksforgings.co.uk/manufacturing-processes.asp?gclid=CMyV4NrY48ACFUjHtAodtW0ASg

http://www.sdf-auto.co.uk/contact.html

Edit: Found it on the web, it was Chedham's Yard, Wellesbourne, Stratford-on-Avon.

http://news.bbc.co.uk/1/hi/england/coventry_warwickshire/5354894.stm

Jeff.

Location: Almost but not quite, the far North East of England

Here we have the interesting situation that if a WOF (MOT) tester learned the eye had been heated, the car would be failed, despite it being standard Seven practice for eons. However what the eye dont see...

If the repairer prudently reinforces the often heated eye with weld, or welds a bridge around, it would fail for sure unless disguised! Or unless certified at great cost.

There are advantages with no MOT test.

Bob Culver

Location: Auckland

Jeff, thanks for swift reply and good ideas.

I know Brooks Forging, but did not realise they had a blacksmiths shop.

I will try them (and the others if unsuccessful, and publish the results.

Many Thanks.

Bob, I think your "suggestions" about advantages of no MOT's are right, would my special be accepted as it has a Cambridge ind. suspension, even though it was supplied in the late 40's or 50's?

Clive.

Location: Wolverhampton

re Doug Bakers solution, my car was treated that way, except that a curved piece was welded on and not ground smooth as no need to disguise at the time.

Unfortunately I had no access to negative advice and, due the successive heating over the years and/or effective Girling brakes, and youthful driving, cracks occurred at the commencement of the I section. Have also seen on other cars. So all dismantled yet again and cover plates welded into the recessed area. Unfortunately obvious to an informed inspector, and would not suit a show car.

There is clearance so it is strange Austins did not alter the forging. What was nicely proportioned for the 1923 car was seriously inadequate in 1937, 1935, 1933....

In the day of Sevens loose eyes were a very common problem here. (Not only Sevens. Straight axle Chevs, favourites of farmers on back country roads, also suffered) Many rural roads were metal and very corrugated, and all roads became very neglected during WW2. The situation persisted until the mid 50s by which time cars became more available and Sevens disappeared. Into the 70s it was not uncommon to hit serious pot holes and rough patching on major roads, but not now.

Incidentally I have seen no comment on Seven antics on corrugations. I presume they do exist in UK! They are not traversed unnoticed!

Bob Culver

Location: Auckland

Ruairidh

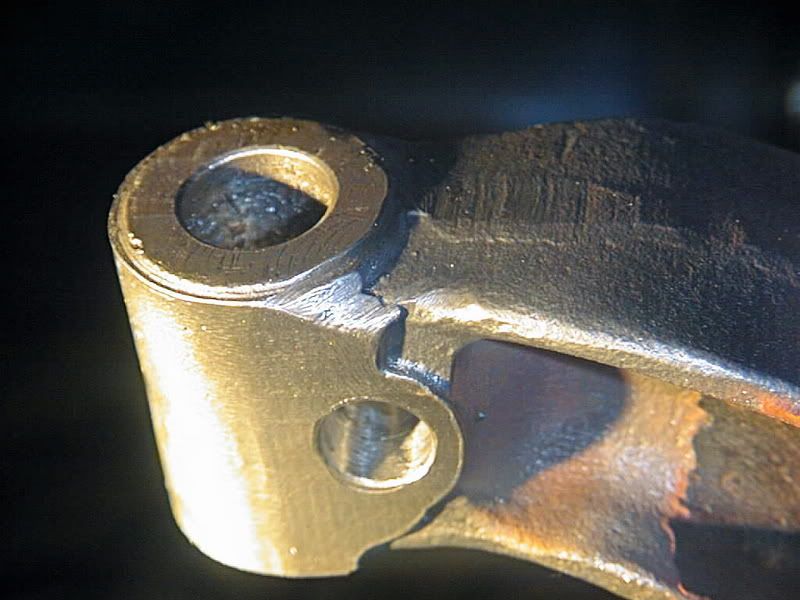

Am I right in the assumption that the axle end pictured has been buttered up with the welder?

Looks like lots of pre heat, and the mig?

Strikes me as a good soloution, though I'd at least MPI the end before use.

The axle on my RL has recently developed some play in one side, the axle eyes having been 'shrunk' once. This may be the soloution for me, get a spare beam sorted out.

Am I right in the assumption that the axle end pictured has been buttered up with the welder?

Looks like lots of pre heat, and the mig?

Strikes me as a good soloution, though I'd at least MPI the end before use.

The axle on my RL has recently developed some play in one side, the axle eyes having been 'shrunk' once. This may be the soloution for me, get a spare beam sorted out.

I agree. It looks good and the buttered weld has been milled to the radius.

I'd be tempted to use TIG if I needed to do that

Charles

The Late Sir Len Southward taught me 40 years ago the method he used when running his motor repair business in the 1930s. his technique was to insert an old king pin into the eye when the eye had been heated to red heat gradually. the eye was then shrunk with peripheral blows struck with a large hammer and a blunt nosed chisel as wide as the depth of the eye. these blows normally encompassed 180 degrees opposite the beam. Once the eye was closed and still hot the pin was driven out before it cooled, if you don't the pin won't ever come out !. The old pin serves to keep the hole round. Subsequently the eye was built up whilst still hot with vertical adjacent weldsruns with H/T rods and an arc welder. a further peripheral weld was done top and bottom to reproduce the original profile. If properly done it is difficult to detect the repair once fettled and painted. The ideal shape for the axle eye should be barrel like with a ring top and bottom. The top and bottom of the eye does all the work as that's where all the leverage acts. . For heavens sake let the axle cool down really slowly to preserve the integrety of the parent metal wrap it in Kaowool furnace Insulation or Fibreglass wadding , sand even ,to allow this to happen. DO NOT QUENCH IN WATER !

Once cool the eyes can be carefully reamed. Do make certain the eyes are parellel and vertical in both planes before assembling. 9 out of 10 axles I work on for others are bent and misaligned. It makes a huge difference to the steering and rate of tyre wear if they are wrong.

I have never had to re shrink or repair an axle treated in this way, or had it subsequently crack.

Location: Wellington New Zealand

I imagine everyone contributing to this post realizes that the Austin axle is very sensitive to being overheated.

However anyone who doesn't know this and plans to attempt a repair should be warned that the steel embrittles if heated above a dull red. Overheated regions become prone to cracking.

I had an Austin Ruby where the king pin eye split from top to bottom. I don't think it had been heated but had instead been bored out and a thin bush pressed in.

Either way the ends of the axle outboard of the spring shackles are very marginal. The centre section between the shackles, where they are bent for lowering, are very lightly stressed so it's much less of an issue.

I would imagine that welding strengthening plates on could easily cause localised brittle areas unless done very carefully and lead to cracks around the weld.

Location: Melrose, Scottish Borders

A colleague of mine who does a lot of work on old cars routinely shrinks kingpin eyes on other makes by simply using the shrink tendency of a weld bead. But other cars have larger holes and are generally less deteriorated.

How the metal is affected is questionable, but very few axles would exists which have not had the cure at some stage.

For those that might be curious Len Southward ran a business here pre war specialising in Seven repairs. He made his pile during and after the war with steel tube manufacture. He established the world renowned Southward old car museum.

Bob Culver

Location: Auckland

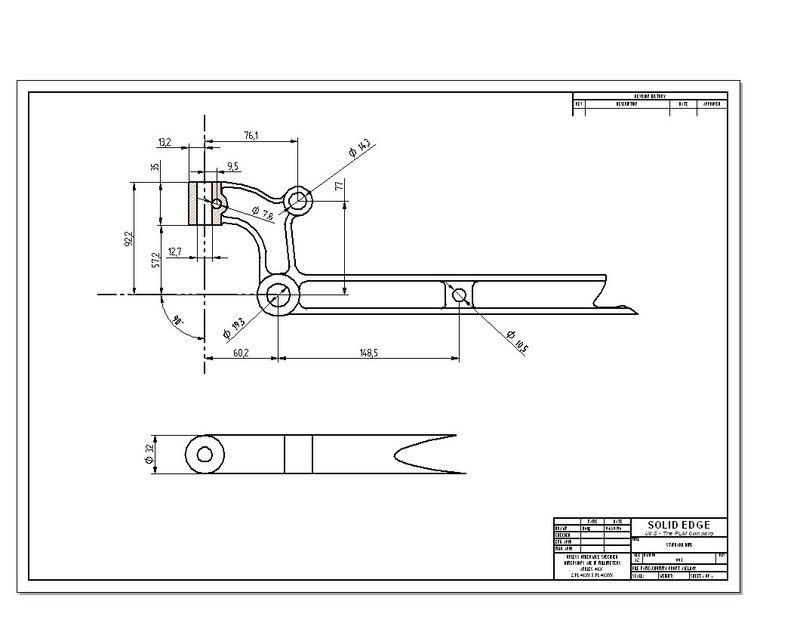

And just in case anyone intends handing the Solid Edge drawing to a repairer, the k.p eye is nominally 12.7, but the exact dimension is less.

I dont know what the recommended interference is. If too tight easy to damage the pin if driven in.

My father acquired our RP in 1940, when Southward was apparently still working in the Seven business. For reasons unexplained he told my father the RP was the best Seven....maybe it was a line he used to sweeten possible customers.

Wartime material shortages and demand, and postwar restrictions enabled Southward to prosper.

Postwar he ran a Merlin powered speedboat. I suppose after driving Sevens he was used to the noise!

Bob Culver

Location: Auckland

The kingpin should be a tight, hand push, fit in the axle, the cotter locks it in place. If you have to drive it in with a hammer it is too tight!

Location: Devon

A colleague of mine who does a lot of work on old cars routinely shrinks kingpin eyes on other makes by simply using the shrink tendency of a weld bead. But other cars have larger holes and are generally less deteriorated.

How the metal is affected is questionable,

"but very few axles would exists which have not had the cure at some stage."

Not sure if this is true of Austin Seven front axles.

Tony.

Location: Malvern, Melbourne, Victoria, Australia.

Some 40+ years ago Geoff LLoyd and I each needed to get axle eyes shrunk and nipped out one lunch time to Almondsbury Forge, which was well known for such repairs. Here we met the boss who quickly let us know he was a coach smith NOT a blacksmith! He was in his seventies and knew all about tempering metal. He could do the job but needed a mandrel 10 thou undersize - his was mislaid. This was to anticipate the resultant hole being slightly barrel shaped. That afternoon Geoff machined up a mandrel, ground a flat on one side and stamped it "A7". We returned at the same time next day and watched as the axles were heated in the forge, dressed into shape and quenched in sperm whale oil. This was the key part. During the afternoon, Geoff had the axles up on a miller and took the eyes out to half an inch.

Thousands of miles later, and coping with hydraulic brakes, the eyes are still tight.

Ron

Location: South Gloucestershire

Hi Tony

It is difficult now to know what the typical mileage of a Seven was in its day before the car was set aside. Most cars did low miles during the War. And it is difficult to know what the typical service history was. Based on a variety of 1950s cars, most seem to succumb in the 130,000-170,000 range, excluding smashes. My RP in constant use, 100,000 by 1957. At that mileage kp eyes had been done at least once and needed again. On light pre 1932 cars axles presumably lasted longer. But many of those cars with fabric bodies etc succumbed early (although the axles lived on!) On heavy Girling cars axle life shorter.

Some scrapped Sevens showed general wear indicative of formidable mileage but could just be due to servicing neglect.

The Austin agents were the main source of parts here and may not have touted oversize pins in the earlier years. Forging closed seems to have been the general remedy.I have also seen axles lined with bronze, a more dubious process. Very thin sleeves easy flowed and turned away another variant.

I suspect by the 1950s when the cars quickly disappeared most would have been treated at least once, at least here near Wellington where Southward reigned!

The front axle was presumably quenched originally from a high temp (below that acheived in welding and above that in conservative reshaping), leaving it somewhat brittle, then tempered (not necessarily quenched) at a faint red. Raising above the latter softens the steel somewhat.

As with spanners, thick non premium metal deflects less than springy thin so building up net beneficial.

Bob Culver

Location: Auckland