Welcome to the Austin Seven Friends web site and forum

As announced earlier, this forum with it's respective web address will go offline within the next days!

Please follow the link to our new forum

http://www.austinsevenfriends.co.uk/forum

and make sure, you readjust your link button to the new address!

This system sounds fine in theory, and will give front/rear compensation. If you have a bowden cable where the outer is free to flex and bend (easier to visualise for a floppy bicycle brake cable) then pushing the outer with the inner anchored has exactly the same effect as the more conventional approach of pulling the inner with the outer anchored. Exchanging a push for a pull may eliminate the need for a pivoted lever to change the sense of direction.

In effect the front and rear brakes are in series, and will always be subjected to the same cable tension.

If you were to forget about the rear brake cable and anchor the pulley solidly to the chassis, the brake pedal should operate just the fronts. This might be worth trying temporarily to see if it works OK or if there is excessive friction.

It's worth bearing in mind that although we think of cable brake operation in terms of movement (because that is what we see happening), the actual brake operation is only as a result of cable tension, shaft torque and shoe pressure. Any movement only happens to take up the initial slack, before any serious braking effort is achieved. If something is really stiff like a brake cable inner, its tension could rise from say 100 pounds to 500 pounds with only a tiny amount of stretch.

Location: New Forest

Sounds fascinating. A photo would be wonderful.

My brain is starting to bleed.

I am familiar with such set ups. Javelin cars operate the throttle via a cable and substitute carbs require the operation to be reversed.

But when the casing is fixed at only one end, it must be free to change end to end distance so cannot run dead straight. Otherwise it can only work by pushing the front axle away. A point made by Ivan and John. An exaggerated version of the traditional Bowden set up (cable looped over the axle) would seem to be desirable. Nevertheless it seems a very high friction complication when, with a fully compensated system, the initial justification for Bowden at the front is largely removed anyway.

The ends of the Bowden casings are moving forward otherwise the rear brakes would not work. As suggested it would seem that the Bowden cable is too stiff, the forward push being resisted by the outer anchorage rather than the brake lever.

Bob Culver

Location: Auckland, NZ

And thinking about this while doing some painting...

Is it a defect that each bowden casing has to transmit half the total available braking tension/compression, whereas in a conventioanl system serves just one wheel, with say 1/4 of the total available tension?

As John observed, the front and rear brakes are effectively in series instead of parallel.

Bob Culver

Location: Auckland, NZ

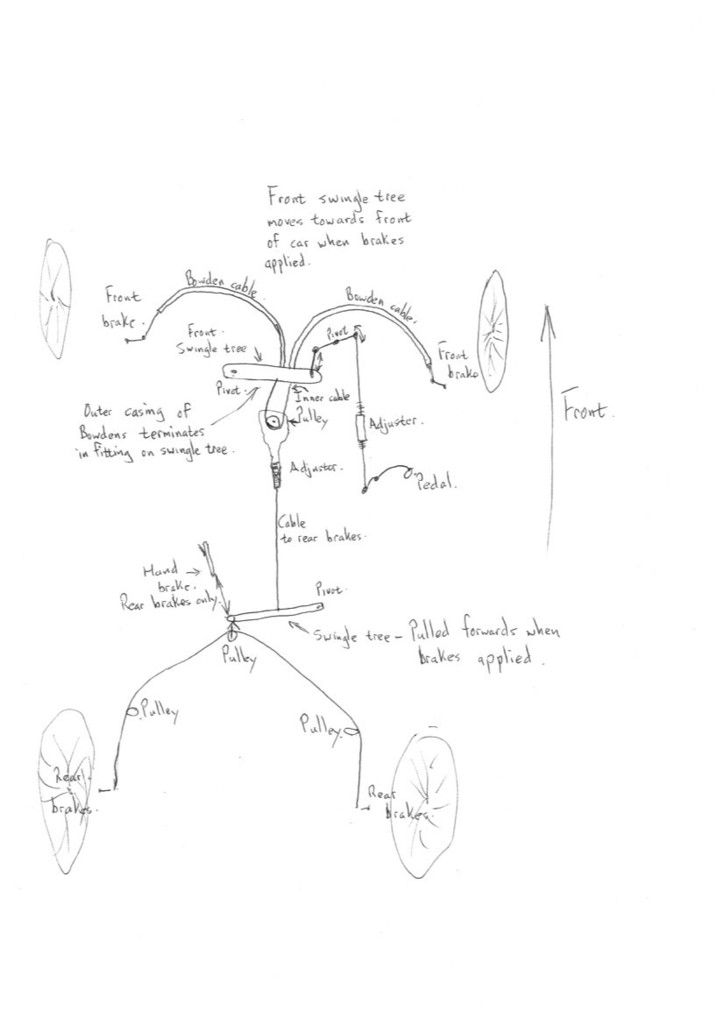

Here is a rather amateur schematic of how my brakes are connected:-

" />

" />

Paul.

Location: Tauranga, New Zealand

Paul, that system should work, but there are a lot of things affecting the proportion of front to rear braking. Get all of these right and it should be good.

I’ve spent a few hours on this today and I’ve made some progress though the brakes still aren’t too good. I can get all four to come on now, though not with much force, but the fronts are not coming off sufficiently to clear the drums when the pedal is released. I guess this could be because the only springs are the Austin springs and there are no coil springs between the clevis and the lever as usually found with Bowdenex systems? Alternatively it could be because there is drag in the cables, but as mentioned they’re nice and free when disconnected. I can’t see anywhere that they’re pinching or being trapped.

With the aid of my long-suffering wife I fiddled around underneath the car watching what happens when the pedal is pressed and making adjustments to get to where I’m at now. The connecting bracket underneath (the one with the pulley which the front cable runs around and which has the single cable attached from the rear brakes) has reached the end of its adjustment now and I can’t get any more travel out of the front swingle without it pulling on the rears. I think if I could effectively lengthen the cable running to the rear brakes somehow (which I think I would achieve by lengthening the connecting bracket) then the front swingle could move further forward and apply more pressure to the fronts before it started pulling the rears. Maybe I should make another, longer bracket unless I can find a way of adjusting the rear brakes elsewhere. Would I achieve the same effect by backing off the brake shoes?

Paul.

Location: Tauranga NZ

In an attempt to counter movement between frame and axle, many cars had cable brakes through conduits, but the latter were primarily just guides and tolerably straight. The Seven Bowdenix installation got hooked on the notion that looping over and pulling from the front assisted, but this should not be necessary with a conduit, and just introduced a lot of friction.

In this application instead of just being guides resisting some component, the conduits are effectively the means of applying the brakes. The application mechanism is as if each loop was grasped and tugged forward, or out of line. The conduit does not just guide but the whole braking for the whole car has to transfer from the conduit to the cable. Friction is huge. To make matters worse all input is via just two cables. Apparently so much friction that no effective relative motion is occurring beyond the loop. Is more pedal travel available?

How do the real mechanical engineers describe it all?

Bob culver

Location: Auckland, NZ

Here is the connecting bracket under the car, linking the front and rear brakes. This is before it was tensioned by adjusting the length of the rear cable:-

And here is the front swingle tree just infront of the connecting bracket:-

Paul.

Location: Tauranga NZ

Not sure that a normal Bowden coiled wire outer sheath works all that well when forced to transmit the full brake thrust as opposed to its usual job of guiding the inner stranded wire core.

I could imagine the wound sections might collapse together (bit like a coil bound spring)and skew sideways onto the core (especially as it is forced to work in a curve, opening up the coils) which will seriously bind the front brake system.

The whole 'compensated' brake assembly strikes me as much too complicated with many pivots all causing friction and lost motion.

Tony.

Location: Malvern, Melbourne, Australia.

Not to mention when looking at the construction weighing about half as much again as the chassis, requiring much braking effort

Tony.

Location: Malvern, Melbourne, Australia.

Yes it is a fairly solid bit of kit! It's aluminium though - not as heavy as it looks.

Paul.

Location: Tauranga, New Zealand

I think Tony has spotted the obvious which we all rather overlooked. Using the conduit in compression is fine for the likes of a throttle connection but 2cwt on the pedal is not uncommon in Sevens, 1/4 of a ton or so compression on a tight turn. On the other hand, the hanbrake of my 1960s everyday car operates with the casing in compression (the cable links to one wheel, the casing to the other). Cable turns through a large radius 90 deg. I have a pile of rear shoes so often use the handbrake for stopping.. but may reconsider.

If it is not a very old recorded construction the special will have to be certified before registering. I would be intrigued to see what a typical self styled "expert" inspector makes of it.

Incidentally, has anyone used the Bowden conversion directly without the loop? Would seem quite logical and like many cars of the time.

Bob Culver

Location: Auckland, NZ

Hi Bob,

I need to think about this a bit more, but isn't this just equal and opposite forces and all that? Even though the swingle tree is moved it effectively pulls on the inner.

Fortunately my Special is already on the road, registered and has a WoF (MoT) - I'm just not sure it's going to get another WoF with the brakes the way they are!

Paul.

Location: Tauranga NZ

Yes I thought at first that the cables would be longish and fairly straight, but now see that they form a 180 degree arc, and I agree that it would create quite a bit of friction. I assume, Paul, that the brakes were like this when you bought the car?

Ivan

Location: Wellington NZ

Hi Ian,

Yes the brakes were like this when I bought the car. I wasn't expecting too much from Austin Seven brakes but these were virtually non-existent and on checking it out I discovered the fronts weren't coming on, all the effort going to the back brakes. I think I should be able to compensate for any friction in the fronts by adjusting the pull on the swingle arm which pulls the rear brakes on.

Regards

Paul

Location: Tauranga NZ

Hi Paul. I have given this more thought. A free bowden cable does indeed have equal and opposite forces on its outer and inner, i.e. the inner tension equals the outer compression. "Bowdenex" cable was a refinement for high-force applications which used square section wire for the outer, to better resist the high compressive forces without deforming. Of course, in a conventional bowden arrangement the outer may not be completely free if it is for example clamped to the same chassis at both ends. In this case some of the compresssive force is relieved from the outer and borne by the chassis instead. In the extreme the outer would be clamped all the way along its length in the manner of a conduit, and 99% of the compressive force would be relieved from the outer and transferred to the chassis. Your setup relies on being a free bowden arrangement however.

With no friction, your setup has a tension of let's say 100 lb in both front inner cables at a particular pedal pressure, measured at the "sending" rear end of the cables. It has a compression of 100 lb in both front outer cables at the same point (from the brake pedal via levers). The tension in the common cable going back from the pulley centre to the rear will be 200 lb, and the tension in the rear cables would be 100 lb each were it not for the rear swingle arm. The rear swingle arm will reduce the rear tension, biasing the braking effort to the front.

If there is friction in the front bowden cables, the frictional force is subtracted from the tension at the "receiving" wheel end. To take an extreme case, the tension in the inner cable at the wheel end could be reduced from 100lb to 60 lb. The compression in the outer cable at the wheel end will also be reduced from 100lb to 60 lb. The rear brakes, being fed via friction free open cables, will still receive their full whack.

Its my experience that frictional losses in curved bowden cables build up disproportionally with the tension applied at the sending end. With a worn or poorly lubricated cable I wouldn't be suprised if one could even reach the point where there is a maximum tension at the receiving end which couldn't be exceeded no matter how much tension was applied to the sending end.

To digress slightly, one way to reduce the friction problem is to swap large cable tension with small cable movement for lower tension and larger movement. This is now done on bicycle brakes by the use of effectively longer levers at both ends of the cable.

Location: New Forest

After much thought and a fair bit of help from this forum, including Ian and Dave who contacted me by email, I've finally got the brakes working to an acceptable standard. I thought I should report back and detail what the problem was. In fact it wasn't one problem but a combination of things, which together caused an imbalance to the extent that the front brakes weren't coming on as all the effort was going to the back brakes. There was sufficient friction in the Bowden cables for the back brakes to "pull against them" without the front brake shoes reaching the drums.

Although when I disconnected the Bowden cables I could pull and push the inner cable fairly easily by hand the drag increased with the load which then caused the back brakes to come on. (A look at my rather rough schematic further up this thread might help in understanding this). The vehicle has been sitting in storage for some time so I suspected dry grease or dirt inside the cables so I removed the grease nipples from half way along the Bowden cables and using plenty of penetrating oil and an air line blew out all the old grease/oil or whatever was in there from the centre outwards. I did this many times and finally lubricated the cables with a thin oil. This made the inners easier to move than before - but the front brakes still didn't come on.

I couldn't see any straightforward way of making the fronts operate any more easily so decided that increasing the force needed to operate the rear brakes might correct the balance issue. I did this using two springs, one stronger one attached between the connecting bracket and the chassis which the front brakes pull against before the rear brakes move and a second weaker spring attached between the rear swingle tree and the chassis. The cable running to the front brakes pulls against these springs and the front brakes are now pulled on before the rears move. The two new springs can be adjusted for tension.

Whilst I still have some fine tuning to do all four brakes are now working, with the fronts coming on first. A huge improvement!

A big thanks to everyone who gave thought to this and offered helpful suggestions as to how it might be resolved.

Paul.

Location: Tauranga NZ

Hi Paul

I think you are trying to push it uphill. Some handbrakes do use the conduit in full compression but seldom applied at full force. In conventional applications friction is incidental to the pull and push. In the system you have the whole push is deliberately transferred from conduit to cable. One of the most experienced contributors regularly recommends abandonment of customary Bowdenex system on the basis that too much friction and no better than conventional. Yet this is just incidental friction from operating one wheel, not the transfer of half the total braking force from conduit to cable.

Whoever devised it deserves Brownie points for lateral thinking, if nothing else.

I would love to take it around the testing stations for a w.o.f! The regulatory authority proclaims that their ex bullock cart "machanics" are all expert.

Bob Culver

Location: Auckland, NZ

WoF time coming up shortly Bob. Could be a challenging time for all concerned!

Regards

Paul.

Location: Tauranga, New Zealand

Clearly its a cold winter in NZ with all these kiwis parked on the net..

In Invercargill we are awaiting news of the trip to the MOT with interest

cheers

Peter

Location: NZ

In NZ the Vintage Car Club (which is a national body covering all makes) issues, in accordance with the V.C.C Technical Code, what is known as a Vehicle Identity Card. Now of course this system is not perfect and can be abused by dishonest owners providing falsified information, however any application is vetted by the club register, and the car is inspected by Committee members of the local VCC Branch so holds some validity. In my experience if you present one of these Identity Cards to the Tester it greatly eases the WOF (MOT) inspection process, the tester is far less likely to apply modern car standards.

Some of us do still use our cars even during the darkest depths of winter, I must admit though, up here we barely have a what you can call a real winter, although I did get caught in a brief Hail storm last week!

Location: NZ

Thanks Ian that's good advice. I'll take my Vehicle Identity Card along with me in the hope of smoothing the passage through the Warrant of Fitness test. I'll report back in due course, but it will be after I've had a couple of weeks in warmer climes. I think "winter" is a relative term!

Regards

Paul.

Location: Tauranga NZ

On the NZ winter theme, in the 1960s I was transferred from windy Wellington to much colder Dunedin. I departed the ferry at Christchurch in my RP very early on a bleak winter morning and set off on the 240 mile jaunt. With the cold, and then no other traffic on a Sunday morning, on the trip across the plains I thought I was in Siberia. The car had no handbrake gaiter and other vents so despite wearing all the heavy clothes I owned it was bitterly cold. Near Dunedin saw snow close up for the first time. Curiously, despite living outside, and regular 25 deg F frosts, the car on 6v used to start OK every morning. Assisted only by an old coat over the bonnet. And no antifreeze!

(In howling cold southerlies for which Wellington is renowned, my car with SAE50 could not make top gear on the flat! But I was once pulled over for doing 60 mph the other way!)

Bob Culver

Location: Auckland, NZ

Paul,

Disregarding the foot pedal bits, if each brake lever required A given amount of movement to apply the brake, the way you have drawn the rear swingle tree lever you would have double that amount being applied to the rear brakes.

I realise your scale may be a little out but it would still multiply the distance moved as drawn.

If it was connected directly to where you have shown the handbrake lever (no swingle at the rear) then all brakes would receive the same travel.

Would this help to prevent the rear brake from having preference over the front ....

I am disregarding friction just thinking of levers and mechanical advantage, just looking at things from a different angle.

Roger

Location: Haverfordwest

Hi Roger,

I see what you're saying but looking at the swingle for the rear brakes, if the force pulling on the rear brakes moves over a greater distance than the distance moved by the cable coming from the front which is applying the force (which it is) then surely the force applied further out from the pivot is proportionately reduced? Put another way, imagine pulling on the swingle by hand adjacent to the pivot point. If the load is on the end of the swingle furthest away from the pivot (and your hand) the amount of force you're able to create at the far end of the swingle will reduce the longer the swingle is, even though it will travel over a greater distance?

Perhaps there's a mechanical engineer on here who can explain this?

Regards

Paul.

Location: Tauranga NZ

John Cornworth emphasised the point that once operated you can largely forget the movement and just consider the tensions, in which case the rears are less than the assumed frictionless fronts because of the lost leverage in the swinging link.

I guess most did levers at secondary school and most are familiar with torque wrenches. To operate grasped half way down shaft, have to pull twice as hard for the same "leverage".

Bob Culver

Location: Auckland, NZ